Neil Crawford accuses government of ignoring warning signs over not-fit-for-purpose compliance routes

The Studio E Architects associate who was the final project lead for Grenfell Tower’s refurbishment has said an unfit-for-purpose regulatory system that allowed multiple compliance routes for products played a major role in the tragedy.

On his third and final day of evidence to the Grenfell Tower Inquiry yesterday, Neil Crawford said the UK government had ignored warning signs that its regulatory system for buildings was unsafe while the multi-track approach to approving products had exacerbated the situation.

Asked what he would do differently on the project if the clock could be turned back, Crawford – who is only part-II qualified and cannot legally use the title “architect” – said he would want to work to better Building Regulations than the 2010 ones under which Grenfell was refurbished.

Crawford said he would want a system more in line with that implemented last year after the Hackitt Review, although he admitted it was arguable whether the 2019 regs go far enough.

“Clearly the risks of the current regulations at the time the building was built were known by government, for example,” he said – referring to the refurbishment project Studio E was appointed to in 2012.

“If you look at the [Environment, Transport and Regional Affairs] select committee information [on the risk of fire spread via external cladding systems] from as early as 1999 you can see the warnings were there about the risk of fire and combustible materials in building.

“The reality is that the Building Regulations aren’t fit for purpose and they’ve led to the regularisation of usage of dangerous and flammable materials.

“Unfortunately the industry only reacts to the regulations that are in place. Therefore you need to have regulations in place that are fit for purpose.

“There was an awareness back then [in 1999], you can see it in the report. Why wasn’t it acted on? It was in Scotland.”

Specifically in relation to Grenfell Tower, where fire claimed 72 lives in June 2017, Crawford said he believed that the ability of manufacturers to pick from multiple standards to claim their products were safe to use was the biggest safety flaw that led to the fire.

“The specific mistake that I think was made is in B4 [the part of Approved Document B of the Building Regulations that refers to the external spread of fire],” he said.

“When you look at the National Class 0 and having it beside the European class. If you just had A2, you wouldn’t have had that situation where you could have put that panel on a building.”

Crawford, who worked at Foster & Partners before joining Studio E in 2009, said the problem was “definitely compounded” by the ability of product manufacturers to shroud test results in secrecy when they did not provide positive results.

“The panel was allowed to be retested and those results not disclosed because it is still compliant with National Class 0,” he said referring to the Celotex RS5000 insulation that was incorporated into the cladding system used on Grenfell Tower’s refurbishment.

“This is a contradiction and led to the fire.”

>> Also read: Grenfell Inquiry: Celotex fire safety claims likened to horsemeat scandal

>> Also read: Not architect’s role to sign off specialist designers’ work, says Studio E associate

On Monday Crawford referred to fire-safety claims made for Celotex by manufacturer Saint-Gobain Construction Products as misrepresentation akin to 2013’s horsemeat scandal.

At Tuesday’s evidence session, Crawford was asked about the decorative “crown” attached to the top of Grenfell Tower as part of the ill-fated refurbishment.

Asked by inquiry counsel Richard Millett whether he had given any consideration to how the crown may perform in the event of a fire, Crawford said he just viewed the feature as “more aluminium panels”.

In response to a question about measures to prevent the spread of fire from the crown, Crawford said he would have expected any fire to “go straight out to the atmosphere” because the feature was not enclosed.

The Grenfell Inquiry’s phase-one report looked at the night of the fire and how flames took hold of the 24-storey block. It said last year that the decorative crown was the main reason for the horizontal spread of flames across the whole tower, once fire had progressed externally up one side of the building from the flat where it broke out.

“The principal mechanism for the spread of the fire horizontally and downwards was the melting and dripping of burning polyethylene from the crown and from the spandrel and column panels, which ignited fires lower down the building,” the report said.

It added: “The presence of polyisocyanurate (PIR) and phenolic foam insulation boards behind the ACM panels, and perhaps components of the window surrounds, contributed to the rate and extent of vertical flame spread.”

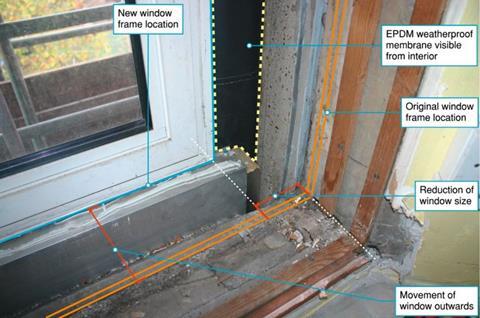

At yesterday’s evidence session, Crawford was asked about the insulation materials used in cavities around the flats’ windows as part of the Grenfell refurbishment.

“Do you know why PIR and sometimes phenolic insulation was packed behind the window jambs and sills rather than the Rockwool that was specified in the NBS specification?” Millett asked.

“I had no idea that had happened until after the fire and I saw pictures of the exposed areas,” Crawford said.

Asked if it surprised him, Crawford answered: “yes”.

The inquiry continues.

1 Readers' comment