A Loughborough University expert has identified the primary cause of failure – and suggests RAAC has the potential to be safe if properly managed

Judging from the news headlines and warnings from experts, knowingly entering a building constructed from reinforced autoclaved aerated concrete is akin to an act of suicide.

John Roberts, a former president of the Institution of Structural Engineers recently said he never trusted RAAC, describing it as an inherently risky material that was mis-sold by manufacturers. Last September the Office for Government Property issued a statement warning that RAAC is life-expired and liable to collapse. And in 2019 the Standing Committee on Structural Safety (SCOSS), with the HSE, IStructE and ICE, issued an alert warning that pre-1980’s RAAC planks had an expected service life of 30 years and should be replaced.

Chris Gorse, the professor of construction management and engineering at Loughborough University, is surprised by the idea that RAAC is inherently dangerous with a limited life. “We have found RAAC that is 40 to 50 years old and has suffered carbonation so the reinforcement is corroded and delaminating in some places, and it is variously cracked and in such a state of disrepair that you would think it is a real risk. But it can still stay in place and sustain loads which is quite surprising.”

Gorse should know because Loughborough University is the only institution to have thoroughly investigated RAAC since the BRE did some testing back in the 1990s. Along with colleagues and a consortium that includes engineer Sweco, materials specialist Lucideon, purchasing consortium CPC and digital specialist IAconnects, Gorse has been researching the issues with RAAC for the past couple of years on behalf of the NHS to inform their remediation programme.

“We’ve done everything that can be done to understand the properties, characteristics and behaviour of this material,” he says. This includes testing it to destruction in buildings earmarked for demolition, testing it in the lab, subjecting it to chemical tests, forensically analysing the structure of the aerated concrete and using this information to model possible behaviours.

This work also includes looking at how the planks were manufactured including the consistency of reinforcement placement and how these were put together onsite. “And that’s where we’ve found the real problem,” Gorse says.

A specific problem

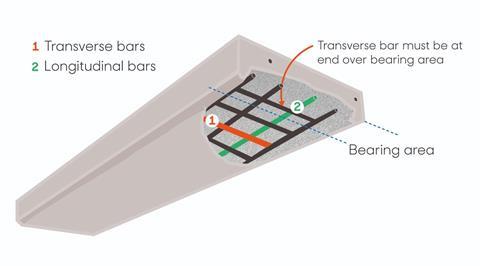

The issue centres on inconsistencies in the placing of the transverse reinforcement bars during manufacture, the quality of which was variable. RAAC reinforcement consists of steel bars extending the length of the planks which are locked in place by a series of perpendicular, transverse bars.

While we have been concerned with the state that RAAC can get into, in the end the real weakness of the material is related to the way it has been assembled on site and the actual bearing properties

Chris Gorse, University of Loughborough

The aerated concrete is so weak – Gorse describes it as a “filler” – that the integrity and positioning of the reinforcement is crucial to its performance. This means that many of the widely flagged issues with the material, while clearly undesirable, are not the primary reason why it fails.

“While we have been concerned with the state that RAAC can get into, in the end the real weakness of the material is related to the way it has been assembled on site and the actual bearing properties,” Gorse says.

The bearing properties Gorse refers to are the section of RAAC plank that rests on the support below. Aerated concrete is too weak to support the loads alone which means that it is crucial that a transverse bar is positioned over the bearing area.

The variable nature of RAAC manufacturing means that transverse bars are not always positioned at ends of the planks over the bearing area, leaving what is essentially a glorified Crunchie bar to take all the loads.

A related problem is shoddy construction. At the time RAAC was being widely used, manufacturers recommended a 40-50mm deep bearing area.

Gorse says site investigations show there are examples of bearing areas as little as 10mm. “There’s a real risk the transverse bar isn’t sitting over the bearing,” he says.

> Also read: Our crumbling schools are just one more symptom of this government’s failure to plan for the future

> Also read: RAAC schools had been due for renewal under scrapped Labour plan

> Also read: RAAC ‘not widespread in social housing’ says regulator

If there was an inherent risk of failure from the day of installation, why should a RAAC roof suddenly collapse many years later? Although there are very few catastrophic failures to be certain, the suggestion is that the failure of structures without proper edge support is triggered by subsequent issues.

The 2018 collapse of a roof at Singlewell Primary School in Kent was thought to have been caused by a lack of reinforcement around the bearing along with recent roof resurfacing works and high temperatures on the night of the collapse, which could have precipitated extreme thermal movement.

Collapsed roof implications

So what does this mean for all those public sector buildings constructed from RAAC? In an ideal world these would be demolished and rebuilt but the huge cost and disruption means this is unlikely or, if the money were to be found, it would take years.

Structures without reinforcement over the bearing area must be identified and action taken even if these look in good condition. It is not clear whether the surveys done to date on schools have included checking the transverse bars at the ends of the planks and the depths of the bearing in addition to checks for spalling and cracking. Gorse thinks bearing checks are unlikely, which means most schools will need to be surveyed again.

A structural engineer can check this by drilling or digging into the aerated concrete at the ends. This is made more challenging if there are services in this area or the RAAC is covered by a suspended ceiling – as many are. Asbestos is also a problem.

Another, related risk factor, according to Gorse, is where maintenance workers have cut through the reinforcing bars. The reinforcement acts as a matrix, with any cuts through it compromising the whole plank.

The good news

The work done by Loughborough suggests that RAAC in good condition with adequate bearing points performs better than originally intended. And examples of buildings with inadequate reinforcement over the bearings could be brought up to scratch by adding edge supports so at least 75mm of the plank ends are supported. This is quicker, cheaper and less disruptive than demolition.

There is a fear because of the reaction at the moment to protect children that we might take remedial action that’s not needed

Gorse thinks the current political crisis and calls for demolition and replacement mean there is a risk that money might be wasted on unnecessary work. “There is a fear, because of the reaction at the moment to protect children, that we might take remedial action that’s not needed,” he says.

Some government ministers are also concerned by education secretary Gillian Keegan’s decision to unilaterally close schools. The potential costs and disruption if this was applied to the entire public sector estate are vast.

A Sky News report quoted Whitehall sources saying that Keegan had opened a “Pandora’s box” that could set a precedent and expose the government to legal and political pressure if it does not universally adopt the same approach as the DfE.

More research needed

Gorse cautions that more research is needed as Loughborough has only looked at healthcare buildings; the findings to date need to be checked against other building types which may have been constructed differently.

A set of consistent baselines also need to be determined that can be used by engineers for analysing RAAC structures. As Gorse says, there are inconsistencies in RAAC surveys, for example there is still a question over what is an acceptable level of deflection or cracking.

Once armed with a full understanding of the risks of RAAC, ongoing monitoring of structures deemed to be safe will be needed in order to check for any changes in condition. Loughborough is investigating how survey data, including photographs, could be systematically recorded and fed into an asset management system, just as built information must be captured as part of the requirements of the Building Safety Act.

Such an approach could help us to live with RAAC – at least for the time being.

No comments yet