JRA’s refurbishment of the grade II-listed former Daily Mail HQ marks a triumph in sustainable heritage regeneration – from retaining 99% of its historic structure to cultivating expansive biodiverse roof terraces. Architects Etain Fitzpatrick and Andy Thomas tell Hollie Tye about how innovative specification and resolving complex detailing challenges have revitalised this London icon for a new era

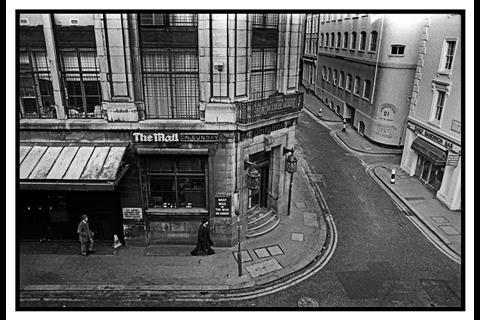

Originally designed by Ellis and Clarke Architects in 1925, The Northcliffe, located south of Fleet Street in central London, was built to house the printing and production facilities of the Daily Mail newspaper. A 1929 addition by the same architects added an attic storey and the building’s distinctive turret.

After the Daily Mail vacated the premises in the 1980s, the building was listed in 1988, protecting its historic facade. In 2001, Rolf Judd Architects undertook a redevelopment, transforming the entire block into office spaces while retaining the facade. John Robertson Architects (JRA) commenced stage two of the project in January 2020, completing the extensive refurbishment in April 2023.

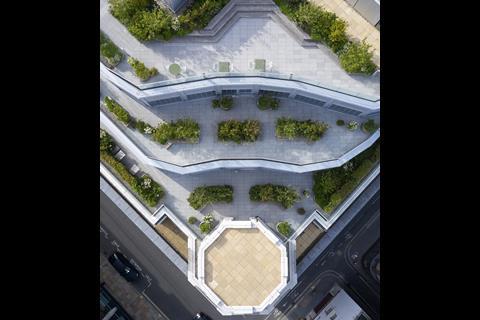

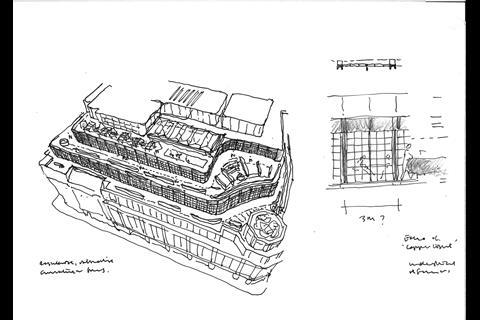

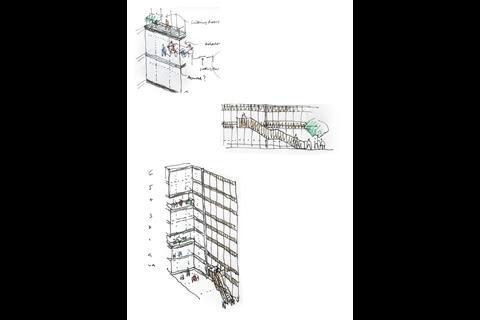

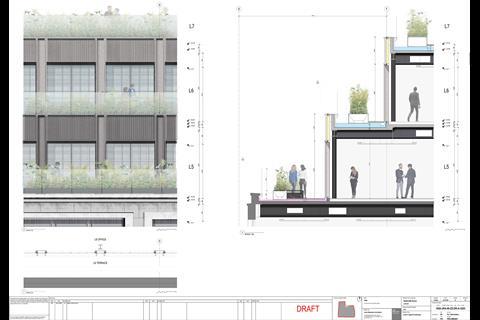

JRA’s vision was to respect The Northcliffe’s industrial heritage while breathing new life into it for the 21st century. Key design principles included extending the upper floors to create roof terraces, reconfiguring the arrival experience through the creation of a new reception and a comprehensive refurbishment to category A office standards. New passenger lifts and end-of-trip facilities were also incorporated.

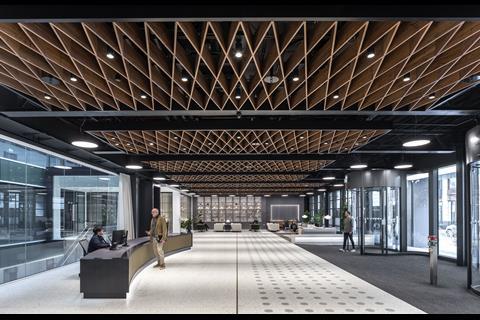

The reception area was designed to create a welcoming and hospitality-focused environment, featuring lounge areas, a library, a quiet meeting room and a cafe. Inspired by the 1920s, the design incorporated strong geometric patterns, rich colours and high-quality finishes.

The project achieved a BREEAM Outstanding rating in both design and construction, a feat accomplished by few refurbishment projects. The building was converted to all-electric power, using air-source heat pumps and photovoltaic (PV) arrays. Three levels of roof terraces, encompassing over 8,000ft², were landscaped with 55 different plant species.

By maintaining the existing structure, the project achieved a 53% reduction in global warming potential, equating to 326kgCO2e/m², exceeding RIBA 2030 targets. Impressively, 99% of the existing structure and 98% of the composite deck were retained.

Etain Fitzpatrick and Andy Thomas of JRA spoke to Building Design about some of the project’s technical complexities. A key challenge was achieving regulatory compliance within the constraints of an existing building. The existing grade II-listed facade presented particular challenges in terms of thermal upgrades, requiring careful detailing and innovative solutions.

The project team benefited from access to structural drawings from the 2001 redevelopment. However, discrepancies between recorded drawings and the conditions discovered during the soft-strip phase required adjustments to accommodate openings in the steel beams for services.

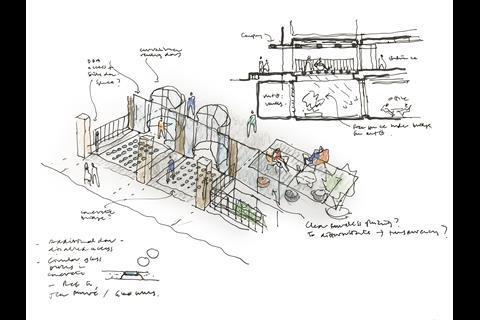

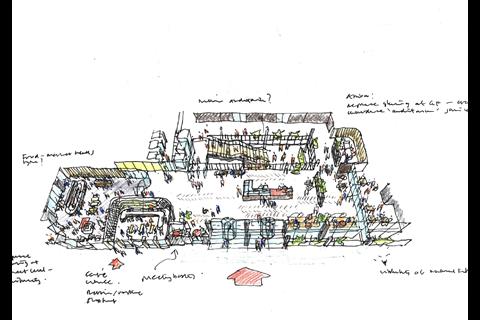

The existing atrium was described as drab and lifeless. JRA’s redesign aimed to activate the space and create a sense of drama upon entry. A new feature staircase directly connects the ground-floor reception to the atrium. Scenic lifts and projecting boxes extended the floorplate and created dynamic features. The atrium was extended upwards, and a new glazed roof was installed. Critically, the existing glazing and spandrel panels were retained, with a film applied to the latter to create a green texture and a new lease of life.

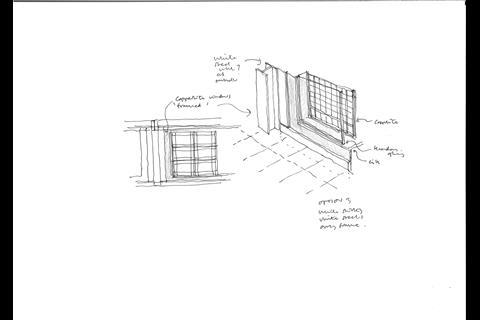

The facade, featuring Crittall-style windows with copperlight subdivisions, was retained and enhanced. The original windows, while beautiful, lacked thermal performance. JRA stripped back the internal linings and improved the thermal performance by introducing secondary glazing. This was detailed carefully to minimise visual disruption and enhance the interior aesthetic. The design of the new upper-level facade drew inspiration from the original windows, creating a unified aesthetic across different eras of the building’s history. The extensions were carefully massed to complement the existing facade while providing access to outdoor roof terraces.

The project involved a variety of material choices. Inside the building, the design team specified handmade terracotta tiles in the lift lobby, from UK manufacturer Darwen Terracotta. The use of modular products, such as terrazzo flooring, aided in creating bespoke designs while minimising waste and cost.

A lifecycle assessment (LCA) helped to inform key decisions, confirming the carbon savings achieved by retaining the existing structure.

Fire safety was a paramount consideration. The design team opened up the firefighting lobby using glazed partitions and doors. They specified non-combustible materials, such as Rockwool mineral wool insulation, throughout. The existing sprinkler system was modified and furniture was chosen with appropriate fire classification for the entrance hall and atrium. The atrium roof incorporates a smoke reservoir and an automated louvre system for smoke extraction.

The extensive roof terraces, landscaped by Townshend Landscape Architects, provide a valuable amenity for occupants. The massing of the extensions and the design of the terraces were carefully considered to balance aesthetics, functionality and sustainability. The landscaping, with its diverse planting scheme, offers year-round visual interest. Lightweight soil structures and GRP planters were used to minimise the load on the existing structure. New waterproofing systems were installed and drainage was integrated with the existing system. The terraces provide great views but also a microclimate for the terrace occupants.

While the first occupants have only recently completed their fit-outs, JRA plans to conduct a post-occupancy evaluation to gather feedback on the building’s performance and how occupants are using the space.

The Northcliffe project demonstrates how a historic building can be successfully adapted for modern use while respecting its heritage and achieving the highest standards of sustainability. Through careful planning, innovative design solutions and close collaboration with the client and contractor, JRA has created a vibrant and functional workspace that is both respectful of the past and ready for the future.

Project details

Architect and principal designer John Robertson Architects

Client International Investment Manager

Development manager M3 Consulting

Services engineer and BREEAM assessor Watkins Payne Partnership

Structural engineer Waterman

Cost consultant Gardiner & Theobald

Main contractor ISG

Heritage consultant KM Heritage

Rights of light consultant Point 2 Surveyors

Planning consultant DP9

Landscape architect Townshend Landscape Architects

Fire engineer Jenson Hughes

Transport consultant Sweco UK

Ecologist The Ecology Consultancy

Acoustic consultant Hann Tucker Associates

Security consultant Troup Bywaters & Anders

Facade consultant Thornton Tomasetti

Facade access and maintenance D2E International VT Consultants

Approved building inspector Sweco Building Control

Structural steelwork Daval

Cladding OAG

Glazed screens and doors Optima

Lifts and lift interiors Kone

Washrooms and end-of-journey facilities Stortfords

Stone flooring Arena

Flooring Tyrell Flooring

Signage Cobal

Secondary glazing Granada

Architectural metal work and atrium stair Arminhall

Drylining and suspended ceilings Celtic

Joinery and reception desk Brown + Carroll

Landscaping Frosts

Metal raft ceilings and reception ceiling Integra

Copperlight windows restoration ASWS

MEP Michael Lonsdale Group

Electrical services Phoenix

Security installation Phoenix Trescray

Fire proofing CLM

Fire protection Thameside

Masonry cleaning and repair Thomann-Hanry

Cycle racks Cycle Works

Decorating H&S

Roofing and waterproofing Knight Ashpalt

Postscript

Calling manufacturers! Gain a competitive edge by understanding what architects value most when making specification choices. Hear from Etain Fitzpatrick and Andy Thomas as they share insights on early engagement, technical support and building successful supplier partnerships. Watch the webinar here.

![Tarmac launches CEVO Asphalts Carbon Calculator for instant data on embodied carbon of asphalt mixes 02[87].jpg](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/9/7/6/2023976_tarmaclaunchescevoasphaltscarboncalculatorforinstantdataonembodiedcarbonofasphaltmixes0287.jpg_435882.jpg)

No comments yet