From retaining walls to street furniture, recycled plastic is gaining ground as a durable, low-maintenance material with serious environmental credentials. We explore how it’s being used across architectural and landscaping projects – and why it’s time specifiers took a closer look

Once seen as a low-grade byproduct, recycled plastic has rapidly evolved into a high-performance material embraced by the construction and landscaping sectors. Its journey from post-consumer waste to durable infrastructure reflects a wider shift toward sustainable, circular design. With growing pressure on architects and specifiers to reduce embodied carbon and extend product lifecycles, recycled plastic offers a compelling alternative to traditional materials like timber and concrete.

Building Design spoke to Nichola Robinson at Hahn Plastics to explore its potential in the built environment and to understand how this material is transforming modern architecture and outdoor spaces.

Why should architects and specifiers consider recycled plastic in their designs?

Recycled plastic offers a sustainable solution that significantly reduces the environmental impact whilst outperforming many other traditional materials. Unlike timber, concrete, or virgin plastics, recycled plastic, which is made from post-consumer waste, supports a circular economy by diverting waste from landfills and reducing the need for virgin resources. This durability makes it ideal for outdoor applications, as it resists rot, splintering and corrosion, as well as reduced damage from “wear and tear” found in high-traffic areas.

If and when products are removed from sites, they are 100% recyclable, providing a closed-loop solution. The original products are made from recycled plastic, and then they go back to source to be recycled once more. An example could be repurposing local council waste to create a long-lasting infrastructure, like an eco crib retaining wall along a motorway. This approach not only gives waste a meaningful second life but also provides exceptional longevity. This example alone boasts a 120-year design life.

What types of plastic waste are typically used in your products and how is it processed?

Our products are primarily made from a secret blend of high-density polyethylene (HDPE), low-density polyethylene (LDPE) and polypropylene (PP) sourced from post-consumer waste streams. The waste is sorted, cleaned, shredded and then reprocessed into our proprietary hanit 1,3 or Ultra material through intrusion, extrusion and injection moulding techniques.

How does the embodied carbon of recycled plastic compare to virgin plastics or other materials like timber or concrete?

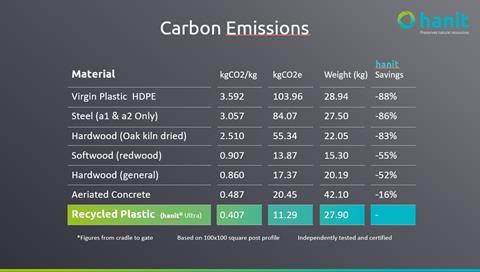

The embodied carbon of recycled plastic is significantly lower than that of virgin plastic, timber, or concrete.

Unlike virgin plastics, which require petroleum extraction and energy-intensive production, recycled plastic leverages existing materials, reducing emissions. Compared to concrete and steel, recycled plastic has a much lower carbon footprint while offering a longer lifespan in outdoor applications. Our EPD score is 0.407, and the illustration below shows how we compare to traditional legacy materials.

How do recycled plastic products perform in terms of durability, load-bearing capacity and weather resistance?

Recycled plastic can be engineered for strength, offering impressive load-bearing capacity and impact resistance. It does not absorb moisture, preventing warping and degradation, and is impervious to rot, insects and chemicals.

Products can be UV-stabilized to prevent fading and brittleness from prolonged sun exposure, meaning they will maintain their strength and appearance even in high-UV environments. When engineered for durability, they perform reliably in extreme temperatures, from -20°C to over 50°C.

What are the fire safety considerations when specifying recycled plastic for external or structural applications?

Fire performance is an important factor in specifying materials and specifiers should check with the manufacturer that the product they specify meets key fire safety standards for external applications with the correct fire rating. Whilst recycled plastic does not burn as readily as untreated timber, appropriate fire precautions should be considered in high-risk environments.

Are there any limitations or challenges when specifying recycled plastic in high-traffic or load-bearing environments?

While highly durable, recycled plastic has distinct mechanical properties compared to materials like concrete or steel. It is exceptionally resilient, particularly under compression, but should be specified appropriately for heavy-load applications. A product’s design is crucial to ensuring optimal functionality. For example, our heavy-duty ground grid, commonly used in truck parks, is engineered to withstand loads of up to 650 tonnes, demonstrating how the material excels under compression.

In some cases, hybrid solutions incorporating recycled plastic alongside other materials may be necessary for structural elements requiring extreme compressive strength. Whether you’re working on ground reinforcement, load-bearing structures, or innovative infrastructure, it’s recommended that you seek expert guidance to ensure your project benefits from the durability, sustainability and performance potential of recycled plastic.

How does recycled plastic compare to traditional materials in terms of cost?

Although recycled plastic’s initial cost may be slightly higher than that of some timber alternatives, its exceptional lifecycle performance delivers substantial long-term savings. Reputable manufacturers will offer an extended warranty period. However, when properly installed, solutions can achieve a 120-year design life.

Are there any specific installation or maintenance requirements that specifiers should know?

Installation of recycled plastic components is straightforward, often mirroring traditional materials in terms of fixing and handling. However, due to its density and flexibility, specific fasteners and installation techniques may be required. Maintenance is minimal, so no painting, sealing, or treatments are necessary, which reduces the longer-term upkeep costs.

What finishes, colours and textures are available for architects looking for aesthetic flexibility?

In the UK, our recycled plastic material is available in black, brown and grey, with new natural tones currently in development. While playground colours are available in Germany, they do not offer the same UV stability, which is why we do not produce them for the UK market.

For projects requiring specific colours, products can be painted with specialist coatings. However, painting can affect sustainability scores, so we recommend considering this in project assessments.

Additionally, we offer varied surface textures, from smooth finishes to textured or embossed surfaces that replicate the look and feel of timber or concrete, allowing seamless integration into modern and heritage designs.

What are the most common applications for recycled plastic in construction and landscaping?

- Street furniture

- Boardwalks and decking

- Retaining walls and crib systems

- Ground reinforcement

- Fencing and barriers

- BioFilter systems

- Bridge components and infrastructure solutions

- Playground structures and safety surfacing

- Flood management components and aquatic solutions.

What innovations are on the horizon for recycled plastic in the built environment?

The potential of recycled plastic in construction continues to evolve. Advances in composite technologies, 3D printing and hybrid material development are extending recycled plastic’s capabilities.

The material is no longer just an eco-friendly alternative – it is a practical, high-performance material that meets the rigorous demands of modern construction and landscaping.

![Tarmac launches CEVO Asphalts Carbon Calculator for instant data on embodied carbon of asphalt mixes 02[87].jpg](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/9/7/6/2023976_tarmaclaunchescevoasphaltscarboncalculatorforinstantdataonembodiedcarbonofasphaltmixes0287.jpg_435882.jpg)

2 Readers' comments