This CPD, sponsored by dormakaba, looks at the requirements of hardware for fire doors including handles, door closers and hinges, alongside CE markings and regulations

CPD CREDITS: 60 MINUTES

DEADLINE: 18 OCTOBER 2019

For more information about Assemble Media Group’s CPD distance-learning programme, click here

Introduction

The integrity of fire safety equipment in buildings has always been a crucial factor when considering the safety of occupants, but in the light of events such as the Grenfell disaster the spotlight has become even more focused on ensuring that such systems are fit for purpose. Everyone involved, from safety inspectors to occupant, needs reassurance that fire doors and related equipment will function according to the regulations and standards in place at the time.

This CPD looks at the requirements of hardware for use on fire doors and will cover CE marking – CE being the certification mark that indicates a product’s conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

It will explore the appropriate door hardware, including handles, door closers and hinges, as well as signage, applicable standards and regulations.

CE marking

The Construction Products Regulation became law in March 2011 and the main changes came into effect on 1 July 2013, when CE marking became mandatory for all products with a harmonised European standard.

The CE mark is applicable to all types of fire door hardware. Hinges are covered by BS EN 1935, emergency exit devices by BS EN 179, panic exit devices by BS EN 1125, locks by BS EN 12209, controlled door closing devices by BS EN 1154, hold-open and free-swing door closing devices by BS EN 1155 and door co-ordinator devices by BS EN 1158.

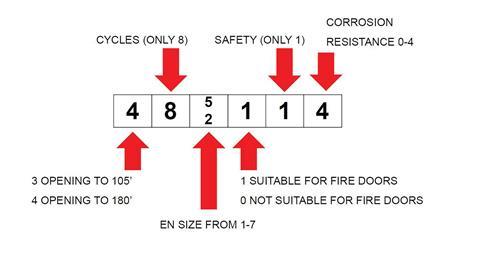

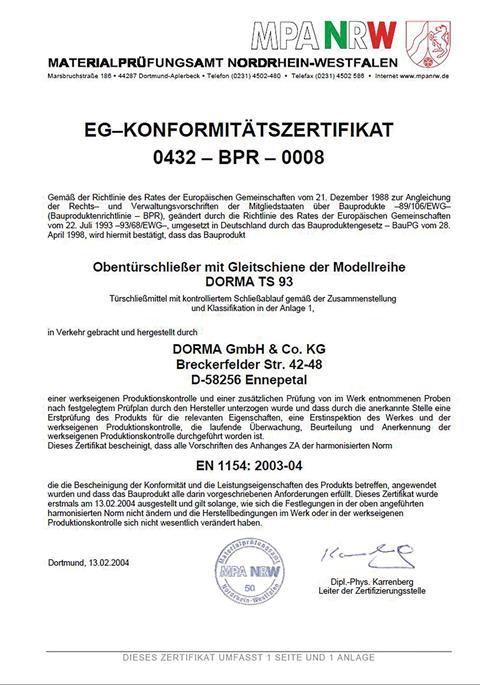

Opposite is an example of a CE certificate relating to a door closer (BS EN 1154), which details the product and, as detailed in the standard, features a classification code in respect of the product’s essential characteristics.

The first digit in the sequence of numbers deals with angle of operation, effectively the angle from which the closing device can shut the door. If a door opens to 180° then a class 4 closer should be used.

The next digit relates to the cycling of the unit. In this case it is 500,000 cycles with an “8” being the only classification used. The closer strength in terms of EN sizes are next. This may be from EN1 (a maximum 750mm-wide door) to EN7 (a maximum 1,600mm wide door).

The fourth digit determines suitability for fire doors – this has to be a “1” for fire door use. The fifth digit is safety, only a “1” can be issued here. Finally, corrosion resistance is detailed on the next digit.

Door closers will also have classification codes detailed on the body along with a CE Mark. In addition to the CE mark, the product must have a Declaration of Performance (DoP) from the manufacturer. Without the DoP, the CE mark is invalid. The DoP details the essential characteristics of the door closer along with other features; these should match the performance rating shown in the CE classification code and the door closer product body itself.

Approved Document B

This document states that a self-closing door is one “which is capable of closing the door from any angle and against any latch fitted to the door”.

To close a fire door from any angle over any latch requires a door closer that provides static force rather than relying on dynamic force. Devices relying on dynamic force may have “fire test evidence” to prove they have been tested on a fire door; however, all this evidence will be on latched doors as they do not have sufficient static force to hold a door closed in a fire. Additionally, these types of products are unable to overcome the latch bolt from any angle.

Mechanical performance of a product is just as important as the fire performance. Using a CE-marked door closer ensures satisfactory mechanical performance. A door closer that is CE marked shows the product is mechanically sound to perform the function of closing a fire door and that it has been subjected to a fire test.

To achieve a CE mark, the product needs only one fire test, which needs to be conducted to BS EN 1634-1. Although the product has been fire tested and shows a “1” in the fire safety classification, this does not provide enough information for using the product on a fire door. Information such as whether the test door was timber or metal, whether it was latched or unlatched, the closer application and the length of the test – was it 30 minutes, 60, 90, 120, 180 or 240 minutes – are all vital to ensure compliance.

To provide such information, many door closer suppliers use the Certifire certification scheme. This third-party scheme details both the mechanical performance and fire performance of the product.

A Certifire certificate details the suitability of a product in terms of door types by collating all fire test evidence for a product and defining suitability for use on timber fire doors (ITT), metal fire doors (IMM/MM) and timber fire doors with metal frames (ITM).

Each door type to which the product is certificated will also have its fire resistance defined; thus a typical scope of approval may say: “Latched and unlatched, intumescent sealed door assemblies consisting of timber-faced and edged leaves with timber, cellulosic or mineral cores in timber frames having a fire resistance up to 120 minutes (code ITT)”.

The EN 1154 CE classification code is also detailed within the certificate to ensure mechanical performance is aligned with fire performance. It should be noted that since BS EN 1154 requires a minimum of EN3 for use on fire doors then Certifire will only detail power sizes of EN3 and above.

Applications for door closers

Door closers have several possibilities in terms of application. On the “pull” side, they may be mounted on the door or the frame. Additionally, they may be door or frame-mounted on the “push” side. All these applications will affect both the mechanical and fire performance of the door closer, which is why a simple one-off test is not sufficient from an application point of view, in addition to giving consideration to the door type and duration of the test.

A Certifire certificate should detail assurance regarding the material the door is made of – timber or metal door – whether it is latched or unlatched, the closer application and the test duration. The certification also details any restrictions that could affect the integrity of the product. Typically these could include uninsulated glass, different product mounting configurations, and whether intumescents are required.

Hold-open and free-swing devices

Self-closing doors can be an inconvenience and in certain locations, such as hospitals, easy access is crucial for the building to function. Hold-open and free-swing devices enable easy access and remove the “barrier” for users.

If ease of access is not considered with manual fire doors, doors may be wedged, giving rise to the potential for a fire risk.

Hold-open devices are ideal for circulation routes since they allow easy, unhindered passage for users. Doors will close on the activation of the fire alarm or in the event of a power failure, assuming they are linked directly to the fire alarm and mains powered.

Free-swing devices are ideal for bedroom doors or any other door where total ease of operation is required and the door needs to be fully/partly closed, for instance in facilities where occupants are elderly, infirm or have a physical disability.

The door may be left in any position by the user, but when the alarm is activated, the door will close. When the alarm is ringing, or power is down, these products will act like a normal door closer. This means doors can still be opened but will close again after the user has passed through.

Operating forces

Fire doors that are difficult to operate are problematic because they can be tampered with and damaged if they prove challenging to operate. They could be wedged open, or in an attempt to reduce operating forces, have the self-closing device disabled, which creates a risk in the case of a fire.

Fire door regulations focus on door closer closing forces, whereas the ease of access regulations must also be considered.

To enable access, BS 8300 and Approved Document M detail required opening forces for doorsets, both of which are linked to the Equality Act 2010:

- Opening force from 0°to 30° of operation is a maximum of 30 Newtons

- From 30° to 60° degrees of operation it is a maximum of 22.5 Newtons opening force.

This is for the total doorset – hinges, seals, latches etc – and not just the door closer. Door closers alone, however, can ensure non-compliance; a check of the door closers’ opening forces throughout the opening cycle (torque curve) should be sought prior to specification to ensure compliance.

So what happens if problems are still encountered with operating forces? Or there are concerns that the doors may be wedged open or the door closer or disconnected?

The Regulatory Reform (Fire Safety) Order is not retrospective in regard to products that complied when originally installed. This only requires a risk assessment, rather than replacement, which means the product could remain in place despite concerns. Conversely, the Equality Act is retrospective and so a replacement can be demanded, resulting in a product that is both compliant with current standards and enables easy access.

Impact of incorrect hardware selection

Those working in the design and build sector are only too aware of building fires in recent years where documented fire door failings resulted in a tragic loss of life.

A review undertaken in 2015 by the Fire Door Inspection Scheme via certificated fire door inspectors uncovered the extent of fire door failures seen on-site. Of those surveyed, 63% stated the most common fault was a fire door not closing properly.

Increasing evidence is also emerging of newly installed fire doors not being fitted in accordance with manufacturers’ instructions, relevant fire test evidence or even in accordance with industry best practice. This increases the need for clients, construction staff and building operators to be extra vigilant in checking the valid certification of products.

Approved Document B – hinges and locks

Looking at other fire doorset hardware, locks and hinges have similar requirements for CE marking and fire certification. They may also carry Certifire certification that details their suitable applications.

“Fire door – keep locked” doors do not have door closers to ensure they remain closed in a fire situation, relying on the lock alone.

In addition, “fire door – keep locked” doors may also need a latch bolt to prevent distortion of the door during a fire. The latch bolt should be a material such as steel that would not melt at high temperatures and so prevent the door from distorting. The certificate will also detail if and what intumescent should be used for the intended application.

Any fire door will have a minimum of three hinges. Intumescent may be required, so it is important to check certification. Again, this may vary from manufacturer to manufacturer.

CE marking of hinges covers both fire and escape doors. A hinge tested for use solely on escape doors can be CE marked but will not be suitable for fire doors. Hinges made of aluminium will be of no use on a fire door – it is crucial to check fire certification.

Signage

In addition to the right hardware, fire doors must be equipped with the correct and relevant signage on both sides of the door, for example: “Fire door – keep shut” or “Fire door – keep locked”. Doors to cupboards or ducts may have signage to one side only.

Approved Document B states that a building should be designed and constructed so there are “appropriate means of escape in case of fire”.

For exit doors, specifying the correct emergency escape hardware is essential. The types to select vary according to building use and type of occupant.

Panic and emergency escape hardware

Doors often feature “push pads”, but these should never be used where members of the public or people unfamiliar with the building are present. These products are only suitable in trained staff situations with fewer than 60 people and should be CE marked to BS EN 179.

If a building has untrained occupants or the number of trained occupants exceeds 60 people, panic devices with either a push bar or touch bar must be used. Push bars and touch pads have a larger surface area and are more easily located and operated in a fire or panic situation. These must be CE marked to BS EN 1125.

The standard requires that the active part of the push bar/touch bar must cover at least 60% of the door’s width.

Panic hardware is generally fitted to final exit doors; however, in certain areas the doors are fire rated. The same procedure in checking for relevant fire certification should be followed as detailed for door closers.

Further guidance on hardware for use on fire doors can be found within guidance papers for the Regulatory Reform (Fire Safety) Order and are free to download from the government website.

Summary

It is important to remember the importance of CE marking when it comes to selecting fire door hardware and to check the CE classification and the DoP in order that the product’s characteristics and suitability can be checked.

Approved Document B requires fire doors to be fitted with a self-closing device, capable of closing the door from any angle and over any latch. Check the certification for application details.

When designing for fire safety, remember to consider ease of access and Approved Document M. There is plenty of guidance and risk assessment information available under the Regulatory Reform (Fire Safety) Order.

Finally, always examine a door hardware manufacturer’s fire test certification, DoP and opening force certification before specifying.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 18 OCTOBER 2019

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contact by email, telephone, fax or post by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy here

No comments yet