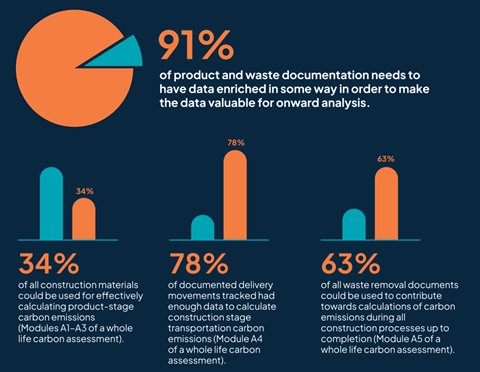

Qflow study reveals 91% of delivery documentation fails basic quality checks, undermining carbon reporting, safety compliance and project budgets

A new report from construction data platform Qflow has found that 91% of construction material delivery and waste removal records fail to meet quality standards, with only 34% accurate enough to support embodied carbon calculations.

Based on six years of analysis covering over 1 million deliveries and removals, the study highlights a widespread data crisis across the UK construction industry. The findings show that 95% of product delivery records contain major issues – from missing weights to incorrect supplier IDs – leaving project teams without the verified data required for compliance and carbon reporting.

This data shortfall poses serious risks as the industry faces stricter regulations under the Building Safety Act and the Net Zero Carbon agenda. The report warns that poor documentation could hinder progress through Gateway 3, where verified material data is essential.

Among the most alarming findings:

- 72% of key deliveries lack critical volume or weight data—information crucial for building safety strategies.

- 80% of contractors surveyed have no structured process for managing delivery data.

- The average time lag between a physical delivery and a digital record exceeds four weeks, leading to procurement delays, reporting errors, and compliance gaps.

With materials accounting for over 40% of construction spend and poor materials management contributing to 5%-11% in budget waste, the financial impact of bad data is significant.

Qflow chief executive officer, Brittany Harris, said: “You can collect as much data as you want, but if it’s not accurate, it’s useless. Improving data quality is a fundamental requirement for the construction industry’s future success.”

The report draws a direct link between data quality and safety, citing the Grenfell Tower fire as a tragic example of the consequences of incomplete or unreliable product information.

![Tarmac launches CEVO Asphalts Carbon Calculator for instant data on embodied carbon of asphalt mixes 02[87].jpg](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/9/7/6/2023976_tarmaclaunchescevoasphaltscarboncalculatorforinstantdataonembodiedcarbonofasphaltmixes0287.jpg_435882.jpg)

No comments yet