Winner of the One Off Small Project of the Year Award 2025, BanfieldWood guides us through the specification challenges present at Room for All Stages

BanfieldWood impressed the judges at this year’s AYAs, as the practice took home the trophy for One Off Small Project of the Year.

In this series, we take a look at the team’s entry project and ask the firm’s director, Simon Banfield, to break down some of the biggest specification challenges that needed to be overcome.

What were the key requirements of the client’s brief? How did you meet these both through design and specification?

The project centred around the idea of allowing a less-abled relative join family gatherings in the garden despite a site that fell away from the back of the house. The issues inherent with this would have meant either the use of permanent ramps, but also was a matter of making this a welcoming and seamless space in the event of use by a disabled person.

The solution proposed was that of a raised, cantilevered structure and an adjoining terrace.

Through a knowledge of large-scale construction methods brought by the structural engineer of practice, the approach of a cast-in-situ structure was proposed and eventually became one of the driving forces behind the project, with its materiality referencing the rough and ready structures seen around the south coast of England.

What were the biggest specification challenges on the project and how were these overcome?

During the early stages of the project, a large amount of brick, rubble and other detritus was found on the site below paving slabs where the project was due to be built. Equalling a few tonnes, this represented a great deal of work, added cost and wasted embodied carbon for the team as the practice was acting as contractor.

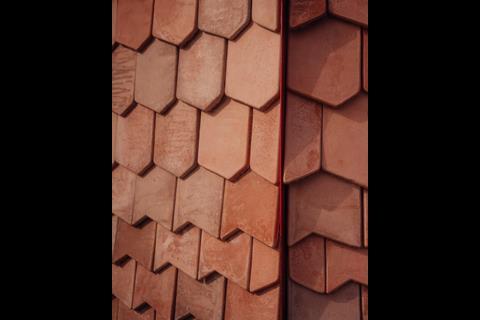

The solution was finding a way to re-use this material, rather than send this landfill – crushing the material up into even smaller elements allowed it to be used as part of a mix to produce bespoke tiles on-site.

A custom mould system was designed and produced in-house cheaply using vacuum forming, and a method was established to allow the tiles to be made on-site by both the build team, but also the client themselves. In the end, over 2,000 tiles hang on the facade, each one unique in colour and texture.

What are the three biggest specification considerations for the project type? How did these specifically apply to your project?

At the time it was a question of cost and lead time – at the smaller end of the residential market, where budgets are tight, bespoke features rarely cover their cost in value uplift, a slight specification decision can make a huge difference in the look and feel of the project and its affordability.

Originally, the upper half of the frame was designed to be a CLT structure. However, due to cost and lead-times, an alternative detail was designed which effectively adapted typical wood fibre insulation and timber frame details – typically seen in passivhaus projects – and used a three-layer board timber internally.

The upshot of this was a quick start on site, a relative cost saving, a unique finish for the client and over a longer period, a greater saving of energy and heat.

Do you have a favourite product or material that was specified on the project?

The timber panel mentioned, which can be seen internally on the roof and the walls is a Douglas-fir three-layer board by a company called Tilly. Not only is it a natural product, bringing a fresh ‘alpine’ smell to the project for the first 6 months, but it looks great and is a lot more workable than a veneered panel. To our delight, it was delivered in five metre long panels, meaning joins were not such a problem to hide in the joinery or internal cladding elements.

Are there any suppliers you collaborated with on the project that contributed significantly? And what was the most valuable service that they offered?

We worked with a company called Iron Designs for the metalwork and galvanising on the balustrades who were incredibly proficient, and we couldn’t recommend enough.

The Tilly board was supplied by Lathams, who were incredibly helpful and efficient.

Jim Johnstone at Construkt CLT originally helped us with the CLT scheme, and guided us on alternatives - he is a true pioneer and driving force of pushing the limits of CLT, and while we didnt work together on this project, we would highly recommend his insight, approach and generosity of his time.

Maxlight supplied the pocket door which helped make the space feel seamless in the summer.

What did you think was the biggest success on the project?

While it may be a trope, the biggest success possibly is that of the different approach and outlook it has given the client and her neighbours towards their houses and the space itself - the house is on a fairly average street, and the approach would usually be that of a rendered 3m box extension to the rear. Through a project which is bespoke in most of its details, this has raised an interest in the surrounding homes of what can be achieved and for the client, has given her a space that she never expected to have a love for - she very generously put a lot of trust in what we were doing while the design changed through the design process and thankfully has said there isn’t a bit of it she’d change now.

Personally, my favourite features are the tiles as they give a unique feel the the facade that couldn’t be achieved with a manufactured product.

Project details

Architect, engineer and contractor BanfieldWood

Client Private

Douglas fir boards Tilly

Glazing Velfac,Passivlux

Glazed door Maxlight Pocket Door

Balustrade metalwork Iron Designs

I-Joists, LVL and wood fibre insulation Steico, Kithurst Homes

Our “What made this project” series highlights the outstanding work of our Architect of the Year finalists. To keep up-to-date with all the latest from the Architect of the Year Awards visit here.

No comments yet