Sponsored by Diespeker, this CPD module looks at the aesthetic and performance qualities of terrazzo, and explores how a material with ancient origins is evolving to meet the challenges of contemporary construction

Learning objectives

- Recognise the two main types of terrazzo and their key properties.

- Know how terrazzo is made.

- Understand modern sustainable terrazzo options.

Once synonymous with art deco interiors and civic buildings, terrazzo has re-emerged in contemporary architecture as a material that delivers aesthetic versatility, technical performance, and, increasingly, sustainability.

The renewed interest in terrazzo is not simply nostalgia, but reflects a wider shift towards materials that deliver low-maintenance durability and reduced whole-life carbon. Whether poured in situ or cast into tiles, panels or bespoke elements, terrazzo also offers a wide range of design possibilities and a proven track record in high-traffic environments.

The history of terrazzo

At its simplest, terrazzo is a composite of aggregate and binder. The version we know today originated in Venice during the 15th century, when quarry workers repurposed offcuts of marble to make flooring in their own homes, setting the fragments in clay or lime mortar. Once hardened, the surface was rubbed smooth with stones and sealed with goat’s milk. This was the birth of terrazzo Veneziano, literally “terrace” flooring, because it was first used on outdoor terraces of Venetian houses.

Throughout the 18th and 19th centuries Italian craftsmen refined the technique: aggregates began to be mixed and graded; lime was incorporated; and marble dust was added as a colouring agent.

After the Second World War, new mechanical polishing machines speeded up installation. Initial success in the UK was driven by price: in the 1950s terrazzo was a cost-effective alternative to marble and granite, and sales soared as the flooring was installed in numerous public buildings such as hospitals, schools, council offices and stations.

Through the 1970s and 1980s as many new offices and private developments shot up, developers took advantage of the cost-effectiveness of terrazzo. When demand slowed, prices increased, and terrazzo fell out of favour. But in recent years terrazzo has experienced a renaissance and is firmly back in fashion.

Terrazzo basics

Terrazzo is a mix of aggregate and binder. Aggregates typically make up about 70% of the mix by volume, and can include natural stones, recycled materials or synthetic aggregates. The size and distribution of the aggregate affect both appearance and performance. Two main binder systems are used: cementitious (Portland or white cement) and resin (epoxy or bio-polymer).

Successful terrazzo installation depends on careful preparation of the substrate, accurate workmanship, and proper curing. Terrazzo can be either poured in situ for a seamless finish, cast in situ, or made into precast tiles, depending on the application.

Applications

Terrazzo is best known as a durable flooring in high-traffic spaces such as shopping centres, stations, hotels and schools. It is often used in healthcare settings too because it is a hygienic surface that is easy to keep clean.

Moreover, its distinctive appearance has come back into fashion of late, with terrazzo being chosen for its aesthetic qualities in setting such as galleries, restaurants and homes.

Resin-bonded terrazzo can be poured into moulds to form furniture components and architectural elements such as:

- Countertops in bars, restaurants and domestic kitchens

- Plinths for retail displays and art

- Original bespoke furniture such as seating and tables

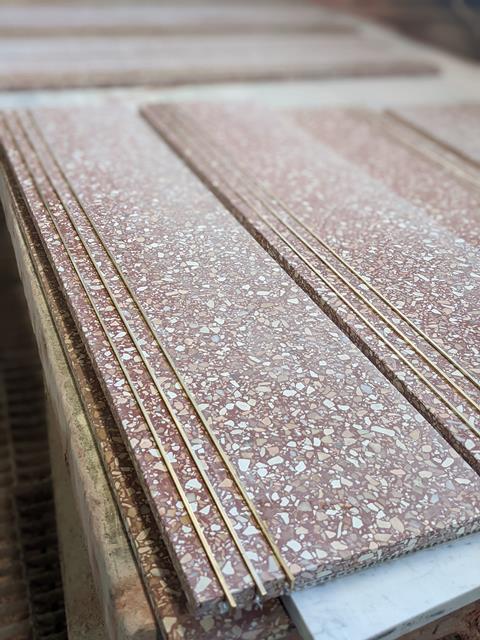

- Stairs – treads and risers can be created from terrazzo

- Cladding (interior and exterior).

Precast fabrication and CNC cutting enable complex geometries, offering new design freedom combined with durability.

How terrazzo is made

Both cement and resin-based terrazzo can be poured on site to create a seamless surface. For poured cement terrazzo, a level concrete subfloor is generally required. For poured resin, the substrate can be a ply floor. The substrate must be dry, clean and dimensionally stable.

Metal divider strips may be needed in cement terrazzo to accommodate movement and prevent cracks, particularly if more than one colour is being used. These dividers can be used to great effect to create detailed designs.

The concrete substrate is first cleaned, repaired, levelled and primed. Depending on the situation a moisture barrier and mesh reinforcement may be necessary too. Then any divider strips and edgers are fixed in place.

Next the aggregates and binder are mixed together in precise proportions, usually in a pan mixer to ensure the aggregate is evenly coated. For cementitious terrazzo, water is added for workability. For resin terrazzo, the resin and hardener are blended according to manufacturer’s instructions. The goal is to achieve a uniform, consistent mix that coats every aggregate particle without trapping air bubbles.

The mixed terrazzo is poured, compacted and levelled with steel floats. Traditional hand casting is the best way to achieve bespoke terrazzo designs. Vibrators or rollers may be used to eliminate voids and ensure dense compaction. For cementitious terrazzo, the layer is usually 25mm-50mm thick. For resin terrazzo, it is much thinner, around 6mm-12 mm.

Next the terrazzo needs to cure to gain strength and hardness. Cement-based terrazzo cures through hydration, a process that requiring moisture and time – typically a few weeks before it is ready for grinding. Resin terrazzo cures chemically within 24-48 hours at ambient temperatures. Temperature and humidity must be controlled during curing to prevent cracking and colour variation.

Once the terrazzo has hardened, it is ground using mechanical floor grinders then polished in several stages. The first coarse grind removes high spots and exposes the aggregate. Subsequent grinds smooth and polish the surface to reveals the beauty of the aggregate and determine the final finish of the floor.

Terrazzo sheets and tiles

Alternatively, terrazzo tiles can be factory made. Thick sheets of terrazzo are compressed mechanically, which adds sufficient strength to the concrete to enable the sheets to be sliced thinly and cut into tiles or larger sheets. Details such as grooves and insets can be added, and the resulting sheets or tiles can be used to achieve a fast installation or used in places where traditional poured terrazzo might not be suitable. Resin-based terrazzo is also available as sheets and tiles. Tiles are generally cheaper than a poured floor and can be used for flooring or on raised surfaces such as countertops or reception desks.

Cement-based versus resin-based terrazzo

Cement is the traditional binder for terrazzo. Marble chippings or other aggregate are added into a grey or white Portland cement base, which can be left natural or dyed using pigments. Cement-based terrazzo has the following properties:

- Extremely durable

- Suitable for exterior use

- A classic appearance

- May require metal divider strips

- Proven longevity and durability

- Can be used to make tiles and precast items like countertops

- Less expensive than resin terrazzo.

Resin-based terrazzo has been around since the 1960s. It is composed of epoxy resin, aggregate and pigments, although newer bio-based resins are now available too, which are more environmentally friendly. Resin-based terrazzo has the following properties:

- Enhances brightly coloured aggregates particularly well

- Less prone to cracking and crazing

- Does not usually require joints

- Can be poured or available as slabs or tiles and can be used in moulds

- Lighter than cement, so more practical for larger moulded items such as big countertops

- While some resin isn’t suitable for external use because it is adversely affected by UV light, there are now resin options that are UV-resistant.

Sustainability

Terrazzo has several inherent qualities that make it a sustainable choice, such as its long lifespan and the fact it can easily be refurbished. Old terrazzo floors can be reground and restored instead of being torn out and replaced. So, if assessed over a building’s full lifecycle, terrazzo often performs more sustainably than materials requiring periodic replacement. Because it contains a large proportion of aggregate, it can also have a significantly smaller carbon footprint than solid concrete, though this depends on the specific properties of the two materials being compared.

There have been many recent refinements to increase terrazzo’s sustainability, including:

- Terrazzo made with recycled aggregates such as post-consumer glass or stone offcuts, or using construction waste as the aggregate – you might even be able to use the waste from a client’s own project. Rubblazzo: Made of London is a terrazzo made from London construction waste set in a cement-free ultra-low carbon mix

- New bio-based resins made from vegetable oil such as Durabella, a biopolymer offered as an option by Diespeker. It contains no chemicals on the Red List of ingredients that are potentially harmful to human health and the environment

- Low-carbon alternatives to traditional cement, in which part of the cement is replaced with GGBS (ground-granulated blast-furnace slag) or PFA (fly ash)

- Use of local stone to reduce the carbon footprint

- Low and zero VOC resins – but always check what other sealers and primers are being used too

- Low-carbon/low-input production featuring, for example, renewable energy or water recycling

- Low-dust production techniques that make for safer working conditions

- Efficient waste handling in production facilities.

These increased sustainablity features mean that terrazzo can count towards LEED and BREEAM certification.

Restoration

In an environment where retrofit is becoming increasingly important, restoring old terrazzo floors can be a great option. Specialist terrazzo companies hold supplies of a range of different chippings so should be able to match the original to effect any necessary repairs. The restored surface is reground, to restore the depth of the original colours, then polished before a final seal is applied.

Design flexibility

A wide range of materials can be used as aggregate aside from the traditional marble chips – which themselves are available in a range of colours and sizes – to give different looks, for example:

- Quartz

- Granite

- Coloured glass

- Shells

- Mother of pearl

- Metallic chips

- Semi-precious stones

- Construction waste.

However, some materials cannot be incorporated in terrazzo, such as organic materials, which are likely to decompose; highly porous materials – certain ceramics or low-quality aggregates absorb moisture and compromise the durability of the terrazzo; and aggregates containing unstable chemicals or compounds that may react with the binding agents. This includes certain types of metals or minerals that could cause discolouration or staining.

Aggregate size significantly affects terrazzo’s appearance, with smaller aggregates creating a modern, polished-concrete-like appearance ideal for minimalist interiors, while larger aggregates produce a more classic, bold and mosaic-like aesthetic. Smaller aggregates are suitable for thinner epoxy systems, whereas larger chips require a thicker, more expensive installation.

Designers can specify tones that complement surrounding finishes, while precise patterns and detailed logos can be created using the metal divider strips. Matched resin and cement terrazzo can look almost identical side by side.

Finishes

Terrazzo can be given different finishes to suit different contexts, such as:

- Polished – a smooth, glossy surface that reflects light strongly and makes the most of design detail. Polished terrazzo is also highly durable and resistant to scratches. Best suited to high-end residential spaces, hotels, and office lobbies where an opulent aesthetic is desired.

- Honed – a smooth finish but matte rather than glossy, providing a more understated and contemporary look compared with polished terrazzo. The finish reduces glare, making it ideal for spaces with natural or artificial lighting, and a slip-resistant surface that is suitable for areas prone to moisture. It works well in bathrooms, kitchens, and commercial spaces such as restaurants and cafes.

- Brushed – a brushed finish gives a soft texture that feels natural underfoot while retaining some visual depth. It offers a tactile surface without being overly rough. Best for flooring in residential areas such as living rooms and bedrooms, and commercial spaces including boutique retail stores.

- Sandblasted – a textured, non-slip surface created by blasting the terrazzo with abrasive particles. This offers good slip resistance, making it suitable for areas requiring safety compliance. It is used for exterior walkways, swimming pool surrounds, and commercial kitchens.

Slip resistance can be tuned through finish and the application of anti-slip treatments – and verified using the pendulum test (BS 7976).

Other performance characteristics

Terrazzo can work effectively with underfloor heating and provides excellent hygiene due to its low porosity.

Installation costs and maintenance

Initial installation costs can be higher than for alternatives, but thanks to its durability terrazzo’s lifecycle cost is relatively low. Damaged areas can be locally repaired and refinished rather than replaced, reducing waste and disruption.

Maintenance typically involves daily sweeping or vacuuming, weekly mopping with a neutral pH cleaner and water, and annual sealing for water and stain resistance. Terrazzo is not stain-proof – it will absorb acidic liquids even with a sealant applied. So avoid spillages of acidic liquids such as red wine, cola and ketchup should be avoided, and spills cleaned up promptly.

Contemporary techniques

The pictures below show some examples of the latest creative uses of terrazzo. It is clear that both aesthetically – and in terms of more sustainable options – this is a material that has come a long way.

Please fill out the form below to complete the module and receive your certificate.

Downloads

Bespoke sample consultation

Other, Size 1.79 mbBespoke sample consultation

Other, Size 1.79 mbBespoke sample consultation

Other, Size 1.79 mbBespoke sample consultation

Other, Size 1.79 mb