Sponsored by URSA (part of the Etex Group), this module explores how glass mineral wool insulation supports sustainable construction by reducing carbon emissions and improving energy performance – covering its environmental benefits, technical performance and practical applications, and showing how it helps architects meet ambitious regulatory and design targets

Construction’s carbon reckoning

The built environment is facing a defining challenge. As of 2021, buildings and construction activities accounted for approximately 42% of annual global CO₂ emissions, underscoring the industry’s significant share of the climate crisis. In the UK alone, construction processes were responsible for over 10 million tonnes of carbon dioxide emissions that year – a 12% increase from 2020, according to government data. More broadly, construction is estimated to contribute to around 50% of all factors driving climate change, including greenhouse gas emissions, resource depletion and pollution.

This data paints a stark picture: nearly half of the emissions fuelling global warming are tied directly to how we design, build and operate buildings. With this knowledge comes a responsibility – and a profound opportunity – for the sector to lead meaningful climate action.

Professional bodies and global frameworks are responding. The Royal Institute of British Architects (RIBA) has introduced the 2030 Climate Challenge, urging architects to reduce operational energy demand and associated carbon by at least 60%, embodied carbon by 40% and potable water use by 40%, using benchmarks from the Construction Industry Research & Information Association and Building Regulations. These performance targets are intended to support the delivery of net zero whole-life carbon buildings by the end of this decade.

At the same time, the RIBA Sustainable Outcomes Guide aligns with the United Nations Sustainable Development Goals, reflecting a global shift towards joined-up thinking in sustainable design. Both frameworks adopt a holistic approach to sustainability, addressing environmental, social and economic dimensions. For architectural practices, this shift means that the design of buildings today is not solely about cutting carbon. It must also consider wider outcomes – including responsible resource use, occupant health and wellbeing, long-term climate resilience and benefits to the surrounding community.

As these frameworks begin to shape planning policy, funding criteria and client expectations, architects and specifiers are under increasing pressure to select materials that offer verified performance and contribute to whole-building sustainability. One solution gaining momentum in this area is glass mineral wool insulation – a material that aligns closely with the goals of both RIBA and the World Green Building Council.

This module explores the role of glass mineral wool in delivering low carbon buildings with a positive impact and demonstrates how it can support architectural practices in meeting evolving regulatory and design expectations.

Learning objectives

- Awareness of the environmental impact of the built environment and the role of insulation in reducing whole-life carbon emissions.

- Understanding of how glass mineral wool contributes to sustainable building design, including its performance, lifecycle benefits and alignment with regulatory standards.

- Knowledge of best-practice specification techniques for insulation products, including addressing the performance gap and meeting energy efficiency targets.

The dual role of insulation

Achieving a net zero carbon building requires addressing emissions across its entire lifecycle – not just during operation. Broadly defined, a net zero building is one where the total amount of carbon dioxide released annually or over the building’s full life is balanced by the amount removed or offset, resulting in no net emissions to the atmosphere.

To accurately design for this outcome, the carbon impacts of both operational and embodied emissions must be considered. Operational carbon refers to the emissions generated from the day-to-day running of the building – including heating, cooling, lighting and equipment. Embodied carbon, by contrast, includes all emissions associated with the extraction, manufacture, transport and installation of materials, as well as ongoing maintenance and eventual disposal.

Insulation plays a pivotal role in reducing operational carbon. By limiting unwanted heat transfer, it minimises the need for energy-intensive heating in winter and cooling in summer. This leads to lower running costs, improved energy efficiency and reduced greenhouse gas emissions. From a regulatory perspective, this directly supports compliance with Approved Document L (England and Wales) and Handbook 6 (Scotland) of the Building Regulations, which sets minimum energy performance standards.

However, insulation products also carry their own embodied carbon footprint. The production process, sourcing of raw materials and transportation all contribute to a material’s environmental impact. As such, the sustainability of insulation cannot be measured by thermal performance alone – its environmental credentials also depend on how it is made. Materials like glass mineral wool, manufactured using high levels of recycled content and renewable energy, offer benefits on both sides of the carbon equation and will be explored further in this module.

Embracing circularity

For the construction sector to become genuinely sustainable, a shift is required from the traditional linear model of consumption – take, make, dispose – to a circular economy model that prioritises longevity, reuse and material recovery.

A circular approach to design means considering the full lifecycle of materials and systems at the outset. Rather than seeing buildings as fixed, finite products, architects are encouraged to view them as adaptable, reconfigurable and – eventually – deconstructable. This allows for components to be reused or recycled rather than sent to landfill.

Within this model, insulation has an important part to play. Products manufactured with recycled inputs and designed for durability align naturally with circular principles. In particular, glass mineral wool is often composed of a high percentage of recycled glass and at the end of its working life, glass mineral wool can be fully recycled.

Circularity also supports resilience and resource efficiency. By selecting materials that support reuse and recycling, architectural practices contribute to a lower-impact built environment while future-proofing their designs against rising material costs and waste regulation pressures.

Understanding whole-life carbon

To make informed design decisions, architects must increasingly engage with lifecycle assessments (LCAs) – a methodology for quantifying the environmental impact of materials, products and buildings from cradle to grave. LCAs form the foundation of a whole-life carbon approach, which evaluates emissions across four key stages:

- Product stage (A1–A3): Covers raw material extraction, transport and manufacturing. For insulation, this might include sourcing recycled glass, delivery to the factory and energy use in production.

- Construction stage (A4–A5): Includes transport of products to site and their installation. Lower carbon logistics and efficient installation methods can help reduce emissions at this stage.

- Use stage (B1–B7): This period accounts for the building in operation – from emissions during normal use, through maintenance, to operational energy and water use (the largest contributor to operational carbon). The insulation’s thermal performance directly positively influences this stage.

- End-of-life stage (C1–C4): Includes building demolition or deconstruction, waste transport, processing and disposal. Materials that are recyclable or designed for reuse can significantly reduce emissions in this final stage.

When conducted thoroughly, LCAs offer a powerful tool to quantify trade-offs and identify where meaningful carbon savings can be achieved – whether through material choice, efficient detailing or circular design strategies.

A building that is operationally carbon-neutral may still carry significant embodied emissions from materials and construction. Addressing the full lifecycle is therefore essential to meet net zero goals in practice, not just in theory.

Glass mineral wool

As architects and specifiers seek materials that support whole-life carbon reduction, glass mineral wool insulation stands out for its ability to deliver environmental and performance-based benefits. Manufactured from a high proportion of recycled glass – typically up to 73%, and in some cases as high as 84% – it helps reduce demand for virgin raw materials while lowering energy use during production. In 2023 alone, the UK insulation industry repurposed an estimated 181,000 tonnes of waste glass, including bottles, jars and automotive glazing.

This emphasis on resource efficiency supports circular economy principles, repurposing post-consumer waste into long-life building components. At end-of-life stage, many glass wool products can be recycled, depending on separation and site logistics, further supporting circular construction strategies.

Glass mineral wool is typically produced in facilities certified to ISO 14001, a recognised environmental management standard. These sites are assessed for how well they minimise energy consumption, reduce water use and manage waste. During the production process, the recycled glass (cullet) and other ingredients are melted and the fibres are then bonded with resin binder to create a mat. This mat is ‘cured’ in an oven, cut to size, and compression-packaged as rolls, slabs or batts. This compression allows more product per vehicle, reducing emissions associated with distribution.

On site, the insulation’s flexible structure allows it to adapt to irregular surfaces and cavity imperfections, minimising thermal bridging and improving real-world performance. This ability to knit together in place means fewer gaps, better thermal continuity and reduced heat loss. Glass mineral wool typically achieves a thermal conductivity (lambda) value between 0.032W/m·K and 0.045W/m·K, enabling compliance with building regulations.

Beyond energy efficiency, it delivers benefits in durability and occupant wellbeing. Glass mineral wool is inert, non-corrosive and resistant to mould or rot. It does not degrade over time and typically lasts the full lifespan of the building – often without any need for maintenance or replacement. It also supports a comfortable indoor environment. By trapping air within its fibre structure, it helps regulate indoor temperatures, keeping buildings warmer in winter and cooler in summer. Its sound-absorbing properties improve acoustic performance by reducing noise transmission through walls, floors and ceilings – important for residential and commercial settings.

With no ozone-depleting substances or greenhouse gases in its composition, glass mineral wool frequently achieves a generic BRE Green Guide rating of A+, reflecting its low environmental impact.

In summary, glass mineral wool contributes to whole-life sustainability by reducing embodied carbon, enhancing operational energy efficiency and delivering long-term performance – all while supporting circular design principles and the wellbeing of occupants.

Meeting the standards with confidence

As the drive toward net zero accelerates, regulatory compliance is no longer just a minimum requirement – it is a critical factor in sustainable building design. For architects and specifiers, ensuring that materials meet or exceed current regulations is essential for delivering future-ready buildings.

Energy efficiency

Glass mineral wool is widely used to meet the thermal performance requirements set out in:

- Approved Document L (England and Wales) – Conservation of fuel and power regulations require new buildings to achieve defined U-values and primary energy targets. Glass mineral wool, with its low thermal conductivity and adaptability in cavity construction, supports new build and retrofit compliance.

- Section 6 of the Scottish Technical Handbook – Similar energy performance standards apply in Scotland, where fabric efficiency and airtightness targets are key to overall compliance. Glass mineral wool enables thermal and acoustic insulation without excessive build-ups, helping designers meet targets.

Fire safety

In addition to thermal regulations, fire safety remains a top priority in all projects. A typical glass mineral wool insulation product is deemed non-combustible, with the potential to achieve a Euroclass A1 fire classification – the highest rating under BS EN 13501-1:2018 – Reaction to fire. This means the product will not ignite, emit smoke or contribute to the spread of flames in the event of a fire.

This performance is particularly significant for high-rise and higher-risk buildings, where Approved Document B stipulates the use of non-combustible materials in key external wall elements. Specifying glass mineral wool in these applications helps de-risk the design and support full regulatory compliance.

Transparency

Alongside technical compliance, the construction industry is also undergoing a transformation in how product information is communicated. The Code for Construction Product Information (CCPI) was introduced to ensure greater accuracy, clarity and reliability in product data and marketing.

The CCPI sets out 11 key clauses that require manufacturers to provide verified, up-to-date and unambiguous information. Glass mineral wool products from responsible manufacturers are now being assessed against these principles, giving architects and specifiers greater confidence in the claims being made.

Importantly, the CCPI is not limited to manufacturers. Architectural practices, consultants, contractors and clients can register as supporters of the code, demonstrating their commitment to product transparency and responsible specification. By becoming a supporter, specifiers signal that they expect the same level of rigour from the products they use as they apply to their own designs. To learn more or to register as a CCPI supporter, visit the CCPI’s website.

Typical applications

As architects and specifiers continue to seek insulation materials that align with sustainability goals and regulatory standards, glass mineral wool stands out due to its flexibility and broad applicability in various building types and systems. From residential homes to large commercial projects, this material has proven its versatility.

Below are some of the most common applications where glass mineral wool can help deliver energy-efficient and performance-driven outcomes:

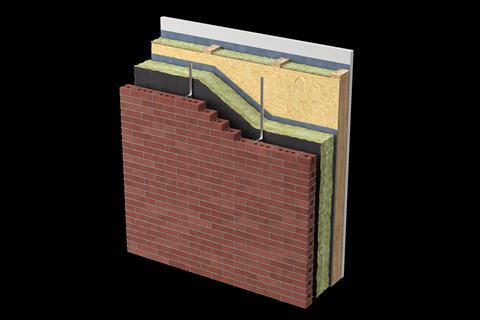

- Masonry cavity wall: Glass mineral wool is commonly used to fill the cavity between the inner and outer walls, creating an effective thermal barrier. This reduces heat transfer through the building envelope.

- Masonry party/separating wall: In addition to insulating external walls, glass mineral wool is used in party or separating walls to minimise heat loss between adjacent properties, improving the energy efficiency of both buildings.

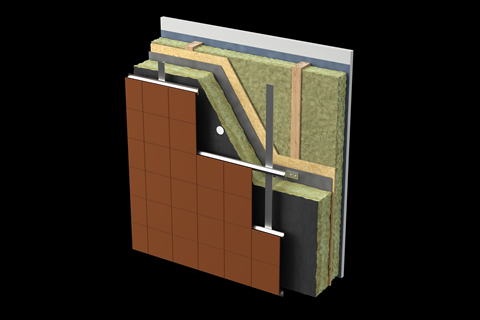

- Timber frame walls and roofs: Glass mineral wool is installed between timber studs and rafters to meet the thermal performance requirements of Part L and Section 6, ensuring energy efficiency and regulatory compliance.

- Lofts/attics: By creating a thermal blanket, glass mineral wool prevents heat from escaping through the roof, reducing energy loss in areas where buildings are most vulnerable to heat escape.

- Twin-skin metal-clad walls and roofs: In twin-skin metal-clad applications, glass mineral wool provides thermal and acoustic insulation. It helps reduce heat loss through walls and roofs while improving soundproofing, ensuring occupant comfort and compliance with building regulations.

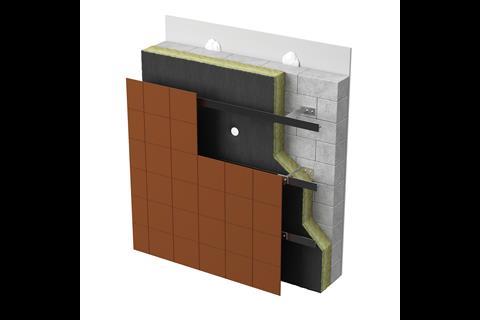

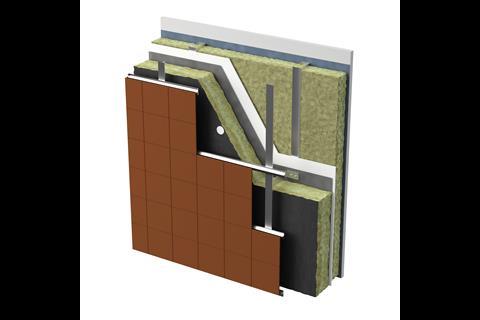

- Ventilated facade and masonry external leaf rainscreen cladding systems: Glass mineral wool provides thermal and acoustic insulation.

These applications demonstrate the adaptability of glass mineral wool, making it an ideal choice for various construction types. However, to fully realise its benefits and ensure it meets both performance and sustainability targets, careful specification is essential.

Specifying for success

When specifying glass mineral wool insulation, it is important to focus on ensuring the material will perform optimally throughout its lifecycle. A successful specification requires careful consideration of both product choice and installation practices, as well as ongoing maintenance needs. Here is how you can specify for success:

- Choose the right thermal conductivity: The effectiveness of insulation is directly related to its thermal conductivity (lambda value). A low lambda value ensures better insulating performance. Select a product with the appropriate thermal conductivity to achieve the desired U-value within the available space. This will help reduce energy consumption and meet thermal regulations.

- Ensure correct thickness: The thickness of insulation plays a crucial role in meeting the specified U-value. While it might be tempting to reduce thickness for cost-saving reasons, this can lead to suboptimal performance and failure to meet energy efficiency targets. Specify the correct thickness to achieve the required thermal performance.

- Confirm compliance with regulations: Always ensure that the insulation you choose complies with the relevant building regulations and standards. Verify that the specified product has been independently tested and has declared performance to ensure reliability.

- Install carefully to avoid the performance gap: Even the best insulation can fail to deliver if installed incorrectly. Imperfect installation, such as leaving gaps or not properly filling cavities, can lead to energy losses and reduced thermal efficiency. Careful installation is crucial to prevent air gaps and minimise thermal bridging, which occurs when highly conductive materials bypass the insulation and allow heat to escape.

By selecting the appropriate insulation product and installation process and addressing these factors during the specification phase, architects and contractors can eliminate the need to over-specify whilst helping to close the performance gap, ensuring the building’s thermal performance meets the design intent.

To assist with making informed decisions and ensuring a transparent approach to product selection, several resources are available:

- Future Homes Hub: This resource offers guidance on meeting climate and environmental goals, including updates on regulations and how they impact new home design. It is a great tool for staying aligned with evolving standards.

- Online U-value calculators: These tools help calculate the required thickness of insulation to achieve desired U-values, aiding specifiers in making precise decisions that comply with regulations and performance requirements.

- Individual manufacturers: Speak to manufacturers directly as they can offer detailed product specifications with in-depth information on material properties and certifications.

Incorporating these resources into your specification process ensures that you select the best insulation solution for your projects, meet sustainability targets, and deliver buildings that perform as intended.

Final thoughts

In conclusion, glass mineral wool insulation offers significant benefits for achieving energy-efficient and sustainable building designs. Its thermal, acoustic and fire credentials make it a valuable material in reducing both operational and embodied carbon, supporting efforts towards net zero carbon buildings.

However, as with any material, careful specification is essential to ensure optimal performance. By considering factors such as thermal conductivity, thickness and proper installation, architects can help ensure that their designs meet regulatory standards and long-term sustainability goals.

Ultimately, the successful use of glass mineral wool relies on a thoughtful, informed approach that balances performance, environmental impact and building requirements, contributing to a more sustainable and resilient built environment.

Please fill out the form below to complete the module and receive your certificate.

No comments yet