The Living Places concept holds the lowest CO2 emissions in Denmark, demonstrating that we do not have to wait for future technology to build more sustainably

Living Places Copenhagen – seven prototypes that hope to demonstrate how the industry can create sustainable buildings – has opened its doors in the capital city of Denmark, recently named the UNESCO World Capital of Architecture for 2023.

Displayed in Jernbanebyen, the old Danish rail district, the project includes five open pavilions and two completed full-scale homes.

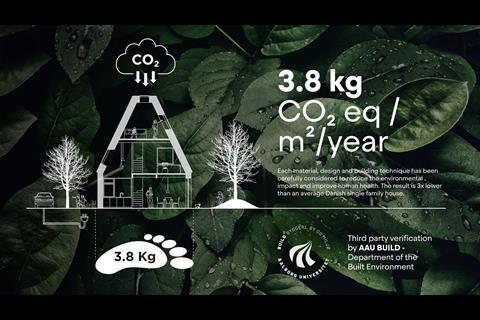

The design team carried out a complete Life Cycle Assessment (LCA); each material, design and building technique has been carefully considered and mapped in terms of the emissions they project compared to a typical Danish household.

Challenging the industry to accelerate responsible and sustainable solutions, the project highlights the need to rethink how we build as well as the materials that we specify.

From 1 January 2023, Danish regulations state that all new buildings must document their environmental impact over a lifespan of 50 years through LCA calculation, and that new buildings above 1,000 square meters must comply with the limit value of 12 kg CO2 equivalent per square meter per year.

Built by the Velux Group, in partnership with Effekt, Artelia and Enemærke & Petersen, Living Places Copenhagen hopes to provide a roadmap for the industry.

The project received third party verification from AAU Build to have a CO2 footprint of 3.8 kg CO2 per square metre per year – three times lower than regulations stipulate.

According to the project team, homes built on the Living Places principles can achieve sustainable ambitions at a cost that matches the Danish market price for a single-family home or rowhouses at scale.

The concept is based on five key principles: homes should be healthy, affordable, simple, shared over time and scalable. These principles can be applied to new or existing buildings and communities.

Designed with a focus on creating a healthy indoor climate – as people stay indoors approximately 90% of the time – the experiment also looked at daylight, thermal environment, indoor air quality, acoustics and outdoor connection.

Inside the buildings, the sloped roof enabled improved daylight conditions with light from roof windows reaching deeper into the plan. Using double high spaces with skylights also improved lighting conditions on the lower floors. Moreover, it enabled the stack effect of warm air for natural ventilation through overhead windows.

The result is a Class 1 classification for indoor climate.

Starting from the ground up, each building component has been optimised for the best constellation of price, indoor climate and carbon footprint with particular attention given to the envelope of the building, where significant CO2 savings can be achieved.

The building itself is carbon negative through the majority of its lifecycle due to the selection of biogenic materials that continually store carbon.

During the development of the project, the team created an LCA calculator that simulates building performance based on material choices.

Specifications for timber frame structural system

(LCA: 3.8 kg CO2 equivalent per square metre per year)

Foundation Screw piles

Terrain deck Lightweight wooden cassette, raised

Exterior wall construction Wooden cassette with cellulose insulation and wooden cladding (untreated)

Interior walls Wooden frame with wood fibre, 1 x fiber gypsum or plywood per side

Floor decks Ribbed deck with visible beams

Roof Lightweight wooden cassette with cellulose insulation

Windows Wood/wood windows (including three-layer glass), GGL with aluminum and wood (including three-layer glass) and modular skylight (three-layer pane)

Solar cells Sunpower

Ventilation Natural

Detailed LCA analyses of various terrain deck solutions were carried out, which showed a significant CO2 saving potential when foundations are laid on screw foundations for supporting a light structure.

Against this background, and in combination with the fact that the buildings at Jernbanebyen are temporary, as well as on contaminated land, screw foundations were chosen. The specification choice was new for everyone in the design and execution team and the ground conditions were particularly challenging due to existing crushed stone, asphalt and rubble.

Significantly longer ground screws were needed than expected, as well as a number of inclined screws to absorb horizontal forces. This resulted in a significantly higher contract price for the foundations, as well as increased CO2 due to an increased amount of material.

Since the design phase and the preparation of the initial LCA analyses, development in the industy has led the team to believe there is little difference between screw foundations in combination with a light floor construction versus a more traditional terrain deck construction with terrain batts and edge foundations.

Specifications for CLT structural system

(LCA: 3.9 kg CO2 equivalent per square metre per year)

Foundation Screw foundation

Terrain deck Lightweight wooden cassette

Exterior wall construction CLT with cellulose insulation and wood cladding (untreated)

Interior walls CLT

Floor decks CLT deck

Roof CLT with cellulose insulation, zink magnesium and asphalt roofing

Windows Wood/aluminium windows (including three-layer glass), GGL with aluminium cladding, wood (including three-layer pane), modular skylight (three-layer pane)

Solar cells Sunpower

Ventilation Mechanical

Living Places can be designed as different typologies with different heights and units and the Velux Group are currently in dialogue with stakeholders to licence the concept into scale. The next step involves building the first full scale Living Places community outside Copenhagen in 2024/25.

The vision is to lead the way within the building industry and show how rethinking buildings can help solve some of the global climate and health challenges.

Lone Feifer, director of sustainable building at the Velux Group, said: “The monitoring and thorough assessment of every product and process has been crucial to reach the results that we are able to present with this project. The materials, solutions, and knowledge are already here - we just need to enable and scale them.”

Living Places Copenhagen will open to the public on Earth Day on the 22 April 2023.

![Tarmac launches CEVO Asphalts Carbon Calculator for instant data on embodied carbon of asphalt mixes 02[87].jpg](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/9/7/6/2023976_tarmaclaunchescevoasphaltscarboncalculatorforinstantdataonembodiedcarbonofasphaltmixes0287.jpg_435882.jpg)

No comments yet