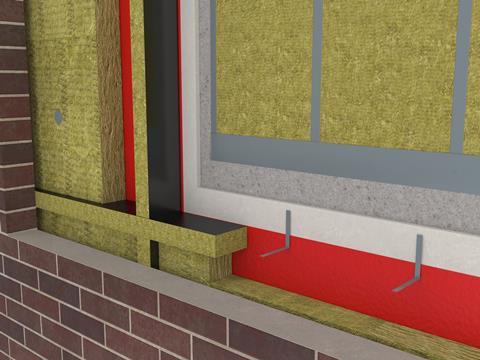

SP FireStop EN has been designed to form cavity fire stops within buildings. Available in various thicknesses, SP FireStop EN features black aluminium foil on both sides and provides a fire rating of EI120 in cavities up to 600mm

A purpose-made solution for cavity fire stopping, FirePro® SP FireStop EN supports architects specifying cavity fire stops for buildings across a range of common constructions. ROCKWOOL has further evidenced the performance of its cavity fire stop solution through specific testing to the curtain wall standard, BS EN 1364-4:2014.

SP FireStop EN has been designed to form cavity fire stops within buildings. Available in various thicknesses, SP FireStop EN features black aluminium foil on both sides and provides a fire rating of EI120 in cavities up to 600mm (subject to the application).

SP FireStop EN was initially tested in constructions with multiple substrates including masonry, concrete, steel frame systems and composite panels with a stone wool core – and while the product was tested to BS EN 1366-4:2021 (Fire resistance tests for service installations: Linear joint seals) on launch, the product has now also been tested to the relevant curtain wall standard 1364-4:2014.

This certification demonstrates performance to designers working on curtain wall constructions. Additionally, specifying curtain wall fire stopping solutions tested to BS 1364-4:2014 aligns with guidance from the Centre for Window & Cladding Technology (CWCT) on best practice for this type of façade construction. The CWCT recently put forward three potential approaches to mitigating performance gaps in curtain wall fire stopping:

Approach one. Test in accordance with EN 1364-4 and use the firestop within the field of application of the test.

Approach two. Test in accordance with EN 1364-4 and use the firestop within an extended field of application; can use guidance given in EN 15254-6.

Approach three. Detail the firestop based on a fire engineering assessment; this would take account of other mitigating measures – for example, the use of sprinklers in the building and the evacuation strategy.

SP FireStop EN will supersede the existing ROCKWOOL cavity fire stopping solution, SP FireStop. The additional field of application offered by SP FireStop EN will provide architects with greater scope, and in the vast majority of cases, the new solution can be included in specifications as a direct replacement.

“At ROCKWOOL, we’re committed to testing our products extensively to ensure built performance and safety,” says Will Wigfield, Product Manager – Fire Protection at ROCKWOOL. “We recognise and agree with new guidance indicating the important of the specific curtain wall standard, and it’s been our first priority among a series of tests we are planning for the product. We believe that SP FireStop EN is an ideal solution for cavity fire stopping applications within our range.”

For more information, technical literature and installation guidance around SP FireStop EN, visit the ROCKWOOL website.