Dyson has teamed up with BD to run a competition for the design of a state-of-the-art sustainable washroom featuring the Dyson AirbladeTM hand dryer.

And the winners are!

The 3 winning entries were announced at The Architect of the Year Awards 2010 and can be seen below.

The 3 winning entries were announced at The Architect of the Year Awards 2010 and can be seen below.

The judges selected a shortlist of 10 entries which can be found here

The winners have had their designs turned into a photo realistic CGI model and will be given global publicity by Dyson. Winning designs will also be showcased in BD as well as on BDonline and exhibited at the Business Design Centre in London.

In addition winning entries received a Dyson Air MultiplierTM fan for themselves and Dyson AirbladeTM hand dryers for their practice.

All winning images were created by Emperor Vision www.emperorvision.com

Dr James Furse-Roberts, FRLA

Intended for an environmental visitor centre run by an educational charity, the Sustainable Education Pavilion provides an outdoor facility where activities, such as pond dipping, can be conducted. Located on the bank of a lake, the pavilion offers shelter, a WC and facilities for washing hands and equipment.

In keeping with the environmental message being taught at the visitor centre, the roof of the pavilion harvests and stores rainwater, which is piped to the sinks and toilet (supplemented by mains water during dry periods). Wastewater from the sinks passes through three reed beds integrated within the structure. These beds treat the water, cleaning it sufficiently for it to be returned directly into the lake. Wastewater from the toilet is piped to a larger wetland treatment system, which is away from the pavilion; here it is naturally treated in a similar fashion.

The roof of the structure is constructed of glass reinforced plastic, which incorporates recycled glass, supported by a steel frame. A permeable fabric mesh covering allows rainwater to pass through while keeping out leaves and other debris. Reclaimed hardwood is used for the decking, cladding of the WC and the screen behind the sinks. The sink and reed bed structure is constructed using Hempcrete and lime render. Hempcrete is a concrete-like substance that contains plant material. It is carbon negative so results in the net storage of carbon-dioxide.

Given the environmental ethos of the client, it is only natural that two Dyson Airblade™ ABO3 units were chosen as a method for hand-drying. They are fast, which is important when being used by groups of students. They don’t produce litter, which requires disposal and might blow around the site.

Their power consumption is minimal, thus reducing their impact on the environment.

They are cost-effective to run, an important consideration for a charity.

A number of submissions took the form of standalone pavilions but the jury felt that James Furse-Roberts’ proposal was the most architecturally sophisticated of this group.

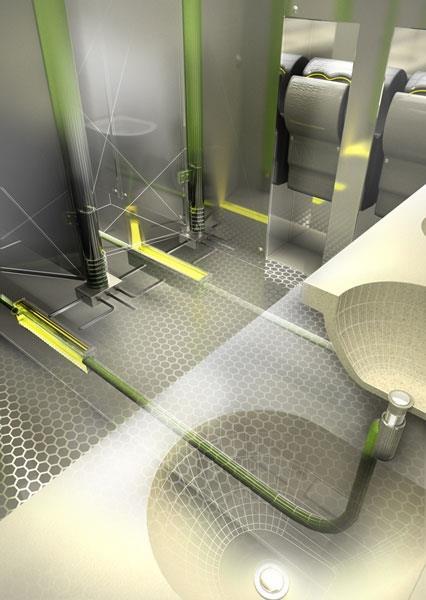

Paul McAneary Architects

The hand-dryer has been located below a counter of reconstituted antibacterial stone, a material that has also been employed for the splash back. The front face of the counter is hinged to allow access to the hand-dryer for regular maintenance. The hand dryer has also been mounted on runners so that it can be pulled out from the counter and cleaned. A skylight extends along the full length of the counter while the use of an LED energy-saving lighting strip behind the mirror and beneath the counter reduces energy use and maintenance costs while achieving the desired aesthetic. Waste is minimised through the use of an automated soap dispenser, pre-mixed warm water and the Dyson Airblade™ hand-dryer.

The jury appreciated the way that this submission demonstrated how the Dyson Airblade™ hand-dryer could be accommodated within an interior of a very minimal aesthetic.

Helen Brunskill, Brunskill Design

This project investigates the potential of reclaiming the wasted energy of the large numbers of people employing washrooms at places such as airports and train stations.

Piezoelectric tiles are employed to generate energy from people walking in and out. A mechanism has been used to harness energy when the cubicle doors are opened and closed. A ratchet is used so that a spring can be wound when the door opens but stays wound when it swings shut. The spring’s stored energy is converted to electrical energy via an electromagnet after the spring has been fully wound. The energy generated from the door ratchet system is used to pump grey water from the sinks to the cisterns. To make the user aware that they are generating energy, a glazed panel in the floor exposes this process to view.

This was one of the most speculative schemes submitted, operating at the edge of technological possibility. The jury particularly admired its daring.