High-density industrial units seek to set new standard for sector

London-based dRMM has successfully completed the construction of Charlton WorkStack, an innovative multi-storey mass timber industrial project.

The development is primarily constructed from engineered timber and sets out to demonstrate new ways of delivering high-density industrial spaces on compact sites. The client behind the project is the Greenwich Enterprise Board (GEB), a social enterprise developer dedicated to providing affordable workspace in the south-east London borough.

WorkStack seeks to address the increasing demand for industrial capacity in a manner that challenges the conventional practice of constructing land-intensive “tin shed” style light industrial buildings. Numerous London boroughs have released industrial land for potential residential development, pushing industrial production away from city centres.

Designed to be affordable, WorkStack is intended to make rental, operation, and maintenance costs more manageable, helping to foster manufacturing activities in central London.

WorkStack contains 14 units ranging in size from 55 to 110 square meters (600 to 1,200 square feet). These units collectively provide workspace for approximately 60 people, with a density of 428 employees per hectare, exceeding the London industrial average of 69 employees per hectare.

Alex de Rijke, founding director of dRMM said, “Why should ‘light industrial unit’ mean an ugly, cold metal shed with bad light and no view out? WorkStack is a demonstration of a new kind of tough timber workspace that is warm, bright and practical. It also gives a powerful message that light industrial can mean socially and environmentally inspirational.”

Occupants of WorkStack include furniture makers, knitwear producers, workwear manufacturers, and a bicycle/motorcycle workshop.

The overhangs of the structure serve dual purposes, functioning as both solar shading and covered delivery areas. Inspired by the concept of a “log stack,” the building employs a straightforward material palette, featuring an engineered mass timber structure with limited use of steel, polycarbonate, glass, and rubber only where required by function or regulation.

The building has been designed to achieve a BREEAM Excellent rating. The cross-laminated timber (CLT) stacked structure has the capacity to sequester 343 metric tonnes of carbon. This represents a 21% reduction in upfront embodied carbon compared to LETI’s 2030 Design Target (350 kgCO₂/m²) and a 44% reduction compared to RIBA’s 2030 Built Target for whole life carbon (750 kgCO₂/m²).

The panelised construction approach not only reduces on-site construction time but also creates a safer and cleaner working environment while minimising material waste. Loadbearing timber walls and ceilings are exposed throughout the building, eliminating the need for additional internal finishes and reducing associated environmental impact.

Michael Finlay, director of GEB added “I first contacted dRMM when searching for new approaches to the building of urban workspace. I was extremely lucky, because I found there a wealth of experience and expertise in the use of timber and particularly of cross laminated timber.

“After a period of thorough planning and development, the Charlton Workstack was devised and eventually built; it now provides outstanding accommodation for fourteen SMEs in an area where space is becoming increasingly scarce. I believe that dRMM have part of the answer to the problems of such scarcity, and also the imagination and commitment to bring new techniques to bear.”

Downloads

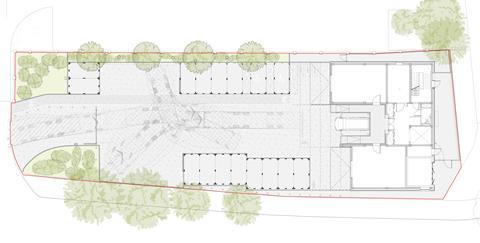

21. WorkStack Ground Floor

PDF, Size 0.11 mb22. WorkStack First Floor

PDF, Size 27.45 kb23. WorkStack Second Floor

PDF, Size 27.33 kb24. WorkStack Third Floor

PDF, Size 51.5 kb25. WorkStack Fourth Floor

PDF, Size 27.09 kb26. WorkStack section

PDF, Size 0.48 mb27. Intensification of light industrial workplace typology

PDF, Size 0.75 mb

Postscript

No comments yet