Developed with material efficiency in mind, the new panel is manufactured from reconstituted stone off-cuts and designed to support both sustainability goals and contemporary facade design

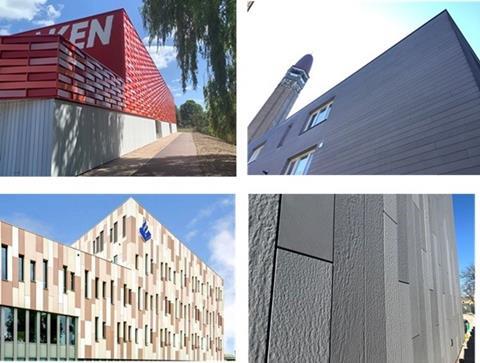

Petrarch has unveiled PlanX, a reconstituted stone cladding panel designed to meet contemporary architectural needs for slimline aesthetics and sustainable material use.

Manufactured in Hastings, UK, PlanX is made from off-cuts generated during the production of larger Petrarch panels, supporting what the company describes as a “retrofit ethic” and material circularity. The panels are available in three standard sizes – 1209 mm x 147 mm, 1514 mm x 147 mm, and 2428 mm x 147 mm – with custom widths available up to 300 mm.

According to the team, the product retains the technical properties of Petrarch’s existing rainscreen solutions, including resistance to weathering, fire performance and a reported 50-year product guarantee. Petrarch also notes that PlanX is BRE EPD-certified, indicating that its environmental performance has been independently assessed.

Described by the company as suitable for a range of sectors – from commercial developments to healthcare and education – PlanX is intended to support both aesthetic requirements and environmental targets.

PlanX adds to Petrarch’s portfolio of facade solutions, which have been manufactured in the UK for over five decades using a mixture of upcycled marble and stone aggregate.

![Tarmac launches CEVO Asphalts Carbon Calculator for instant data on embodied carbon of asphalt mixes 02[87].jpg](https://d3rcx32iafnn0o.cloudfront.net/Pictures/100x67/9/7/6/2023976_tarmaclaunchescevoasphaltscarboncalculatorforinstantdataonembodiedcarbonofasphaltmixes0287.jpg_435882.jpg)

No comments yet