Ventilation systems in commercial buildings are vital to remove pollutants from the air and control temperature and humidity. This CPD, sponsored by Daikin, looks at how ventilation systems can be used to improve air quality

CPD CREDITS: 60 MINUTES

DEADLINE: 21 SEPTEMBER 2018

For more information about Assemble Media Group’s CPD distance-learning programme, click here

INTRODUCTION

Poor indoor air quality caused by insufficient ventilation is an issue for many types of buildings, from residential properties to offices and factories. World Health Organisation (WHO) research indicates that nine out of 10 people worldwide breathe polluted air, with 80% of urban residents being exposed to air pollution levels that exceed the WHO’s limits. It also estimates that globally, air pollution is a contributing factor in one in nine deaths.

This CPD will examine how ventilation systems can be used to improve air quality. It will look at the legislative requirements, design considerations and best-practice approaches. This module will primarily focus on commercial buildings but will also reference the specific requirements for domestic applications.

The purpose of ventilation

During the design of a system, consideration should be given to what the ventilation needs to achieve. Within a building, ventilation has three main roles:

- To provide sufficiently high air quality for people to breathe, by removing pollutants;

- Acting as a medium for delivering heating and cooling;

- Controlling humidity levels to avoid condensation forming and possible mould propagation.

A holistic view should be taken at every point in the design process, and an assessment made as to whether these three criteria are being met.

A number of factors can help inform decisions relating to meeting the regulatory and design purposes of the building as a whole.

Regulatory/legislative requirements

In the UK, Approved Document F (ADF) of the Building Regulations sets a baseline for ventilation in buildings and provides guidelines for ventilation rates in new residential and commercial buildings.

The overarching requirement of ADF is that for every building “a ventilation system is provided that, under normal conditions, is capable of limiting the accumulation of moisture, which could lead to mould growth, and pollutants originating in a building, which would otherwise become a hazard to the health of people in the building”.

In residential buildings the recommended extraction rates are based on the number and use of rooms. Bathrooms, for example, are recommended to have at least 8 litres per second (l/s) of continuous or 15l/s of intermittent ventilation. The whole house must also have a minimum extraction rate that is determined by the number of bedrooms. For example, a property with one bedroom has a guideline rate of 13l/s while for five bedrooms it is 29l/s. When applying these guidelines, consideration should be given to whether the building features a basement or if the property is a self-contained basement, and the level of a building’s occupancy, which will influence the final recommended extraction rate.

For commercial buildings, the guidance can appear simplistic, especially for general purpose offices (with no significant sources of pollution), where the baseline requirement is 10l/s per person. However, rooms within that building that have specific functions may require additional ventilation. For example, for any room housing printers and photocopiers that are in operation for more than 30 minutes per hour the recommended rate is 20l/s per machine. This is because office equipment can emit pollutants, including ozone and organic compounds, that could be hazardous to health.

The 10l/s per person rate is significant because many studies have found buildings with ventilation rates lower than this figure are prone to “sick building syndrome”. This is a group of symptoms that include headaches, poor concentration and fatigue, and is attributed to a poor-quality indoor environment. However, studies have shown that there are minimal or difficult-to-quantify additional benefits to increasing the ventilation rate significantly beyond the 10l/s guideline.

Approved Document L

The non-domestic compliance guide for Part L of the Building Regulations, which is concerned with conservation of fuel and power, also sets targets for air distribution systems. The document offers specific fan power targets for different systems, whether they are centralised, local or utilise heat recovery. However, it may be that there are many types of air distribution systems in use in the building other than the ventilation itself, including chilled water fan coils, washroom extract, or variable air volume (VAV) systems and these need to be factored into the calculations.

Variable refrigerant flow (VRF) and variable refrigerant volume (VRV) system indoor units should not be assessed for Part L using the specific fan power methodology. This is because these systems should be assessed as a whole system based on the seasonal energy efficiency ratio (SEER) and Seasonal Coefficient of Performance (SCoP), so by evaluating the indoor units’ SFP you would double-count the power input to the indoor units.

Design considerations

There are many types of products used for ventilation and increasing the indoor air quality of buildings, from simple through-the-wall fans up to large air handling units.

Rooftop units are a basic concept for delivering heating, cooling and fresh air. As the name suggests, such equipment sits atop a building, with all the components housed in a single product. Return air from the space and fresh air is drawn through the unit and the conditioned air is distributed through ductwork into the building.

Heat recovery

As the increase in insulation in buildings has made them more vulnerable to overheating, there has consequently been an increase in the requirement for mechanical cooling in order to maintain comfort levels in the building. This increase in cooling can be partially offset by implementing a ventilation system that is capable of recovering waste energy from the extracted air through the use of counter flow heat exchangers, cross-flow heat exchangers, or rotary heat exchangers.

Whenever the term “heat recovery” is employed, it is done in the thermodynamic sense, where heat is “useable energy” rather than heat in the commonly-used sense. Therefore it also applies to recovering energy that can be used for cooling processes as well as the heating.

The recovery of heat is crucial, for without it fresh air delivered into the space would be a similar temperature to the air adjacent to the inlet and the rejected air would be similar to the air in the building. The energy held by indoor air has already been conditioned by the air conditioning system employed within the space, therefore any air simply removed from the space is financially uneconomical, since the replacement air must be air conditioned again.

If a heat recovery device is used in the air handler then the majority of the energy in the air leaving the building can be recovered and used to condition the incoming air.

This lowers the load on the air conditioning system and because the heating and cooling requirements are reduced, it also allows a reduction in the capital cost of the air conditioning system. The larger the temperature difference between the ambient outdoor and indoor temperature, the greater the heat recovery effect and therefore the savings.

If the heat recovery element of the air handler requires no power, as with counter-flow heat exchangers, then all of these savings are realised, apart from slightly higher power input on the air handler fans that is required to overcome the additional static pressure of the heat exchange element itself.

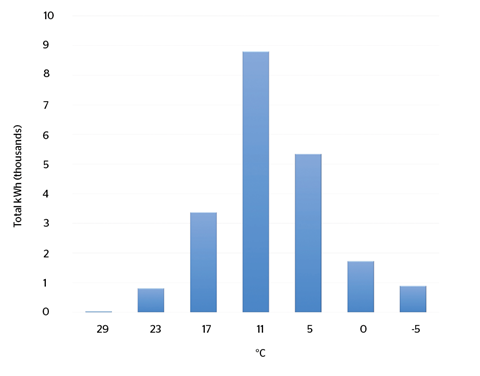

When looking at an example year, the savings add up. In the example on the graph above, it equates to 21MW of delivered energy.

If we assume the air conditioning system has a seasonal efficiency in both heating and cooling of five then this means a power input saving of 4.2MW, which saves nearly 1.5 tonnes of CO2 equivalence and saves more than £500 a year for the client.

So the benefits of heat recovery in air handling applications is clear in terms of energy, CO2 and financial savings.

Sensible and latent heat

Some heat exchangers are designed to exchange “sensible” and “latent” heat. The increase in heat when an object is heated and its temperature rises as heat is added is called sensible heat. Similarly, when heat is removed from an object and its temperature falls, the heat removed is also called sensible heat.

All pure substances in nature are able to change state from solids to liquids, and liquids to gases, with the addition or removal of heat. The heat that causes these changes is called latent heat.

Latent heat, however, does not affect the temperature of a substance – for example, water remains at 100°C while boiling. Appreciating this difference is fundamental to understanding why refrigerant is used in cooling systems. It also explains why the terms “total capacity” (sensible and latent heat) and “sensible capacity” are used to define a unit’s cooling capacity.

During the cooling cycle, condensation forms within the unit due to the removal of latent heat from the air. Sensible capacity is the capacity required to lower the temperature and latent capacity is the capacity to remove the moisture from the air.

Efficiency

Care should be taken when considering the type of heat exchanger to be used for different applications. Latent recovery should be avoided when considering using heat recovery ventilation for areas such as washrooms, toilets, kitchens and shower spaces, since latent heat exchange can also transfer odours. For these applications, sensible heat exchangers can be used to get the benefits of heat recovery without the potential for causing unpleasant smells.

Typically, sensible heat exchangers recover a greater amount of heat – as much as 90% more. The heat exchangers themselves are made from either plastic or metal with high heat transfer capabilities. Care should also be taken to ensure that very cold air is not introduced into the space as cold draughts can cause discomfort and could also cause condensation, negating moisture control.

Some systems are able to perform this function automatically by monitoring the temperature of the airstreams and adjusting the bypass damper to maintain reasonable levels of free cooling while maintaining comfort.

Considering CO2 levels

Since indoor air quality is usually determined by CO2 concentration levels, savings in running costs and reducing carbon emissions are possible by using ventilation systems that provide a varying quantity of fresh air to keep CO2 levels within acceptable limits. This is usually defined around the 1,000 parts per million mark.

The major benefit of controlling ventilation rates through monitoring CO2 levels is that it can adapt to how the space is being used. For example, the system may be designed to serve a space with a peak of 50 occupants – if the space only has 25 occupants then the ventilation rate required could be halved. Of course the ventilation system is not going to know how many people are in any given space, so CO2 monitoring is an ideal way of assessing the demand. Many ventilation systems have built-in CO2 sensors – or are available as options – and work by controlling the fan speeds for extract and supply in order to achieve the target CO2 level. Also, any application in an area with additional high concentrations of pollutants other than CO2 should be considered carefully.

The requirement for filtration will depend on the application, with medical and laboratory air handlers usually requiring the highest levels of filtration. Filters can vary in quality from relatively straightforward “bug catchers” – which prevent larger items of debris from entering the airstream – up to high-level, high-efficiency particulate air (HEPA) filtration, which collects at least 99.97% of particles of 0.3 microns in size (one micron = one millionth of a metre).

Types of ventilation unit

Heat recovery ventilation (HRV) systems consist of an indoor unit and ducting to extract and supply air. Such units are designed to fit in the ceiling void or be close to the areas served. These systems tend to have airflow rates from around 150m3 to 3,000m3 per hour. As with all fan driven systems, the airflow rate is dependent on the pressure of the connected ductwork. The fans will commonly have a maximum available external static pressure of around 250 pascals to 300 pascals. As such, a system might indicate it has a pressure rating of 90 pascals, but this might mean it is capable of 200 pascals but at a lower airflow rate.

At these airflow rates, systems are typically rated with 90 Pa available external static pressure, but they are also quite capable of providing up to 275 Pa of pressure with an airflow of 1,200m³ per hour on the larger units. Note that a pascal is deemed to be equivalent to one newton per square metre.

HRV units usually have options for CO2 sensors and additional filter grades up to F8 grade (under the EN3779 standard). HRV units typically also come with options for hard-wired local controllers and hard-wired contacts for building management system (BMS) integration as well as options for full integration via adaptors to communicate in BACnet, LonWorks, or Modbus protocols. They are also very good solutions for creating additional ventilation, especially when a building’s use has changed or where the incumbent system may be a little undersized.

Large units

Larger air handling units with very high airflow and static pressure capabilities are available for larger buildings, areas where internal space is limited or where an application requires them. These generally fall into two categories: modular and bespoke systems. Modular systems provide a range of options for components such as fans, filters, heat recovery, cooling and heating coils, electrical heater batteries and control protocols, which are combined to meet the needs of the application. These solutions commonly deliver up to 25,000m3 per hour of ventilation. Beyond this point it makes more practical and commercial sense to use multiple air handlers due to the ductwork sizes required and the distance from the space that needs to be conditioned. In these situations a bespoke system will provide the best solution but the lead times are often longer as this would require specific design work and sourcing of components.

Eurovent – Europe’s Industry Association for Indoor Climate (HVAC), Process Cooling, and Food Cold Chain Technologies – independently assesses air handlers, rating them from A+ down to E ratings. There could be options for a large number of components with different efficiencies on the heat recovery wheels or other types of heat exchangers; fan motor efficiencies, whether the system is weatherproofed or can be housed internally; and different air handling modes including free cooling and positive or negative air pressure differentials.

Finally, compatibility among different heating and cooling technologies needs to be addressed. Air handlers with heating and cooling coils can typically be supplied by two differing technologies: chiller or direct expansion (DX) units. Chillers can provide both heating and cooling to the coils and are a very effective way of providing the required capacity with the associated water pump sets.

Using DX to supply heating and cooling capacity is also a very good solution. Capacity control can be achieved by modulating the compressor speeds or the target evaporating and condensing temperatures. Modulating the target refrigerant temperatures is by far the best way to control capacity.

How to take this module

Assemble Media Group’s CPD distance-learning programme is open to anyone seeking to develop their knowledge and skills. Each module also offers members of professional institutions an opportunity to earn between 30 and 90 minutes of credits towards their annual CPD requirement.

This article is accredited by the CPD Certification Service. To earn CPD credits, read the article and then click the link below to complete your details and answer the questions. You will receive your results instantly, and if all the questions are correctly answered, you will be able to download your CPD certificate straight away.

CPD CREDITS: 60 MINUTES

DEADLINE: 21 SEPTEMBER 2018

Privacy policy

Information you supply to Assemble Media Group Limited may be used for publication and also to provide you with information about our products or services in the form of direct marketing by email, telephone, fax or post. Information may also be made available to third parties. Assemble Media Group Limited may send updates about Building CPD and other relevant Assemble Media Group Limited products and services. By providing your email address you consent to being contacted by email by Assemble Media Group Limited or other third parties. If at any time you no longer wish to receive anything from Assemble Media Group Limited or to have your data made available to third parties, contact the Data Protection Coordinator at building@building.co.uk. View our full privacy policy at www.building.co.uk/cpd

No comments yet